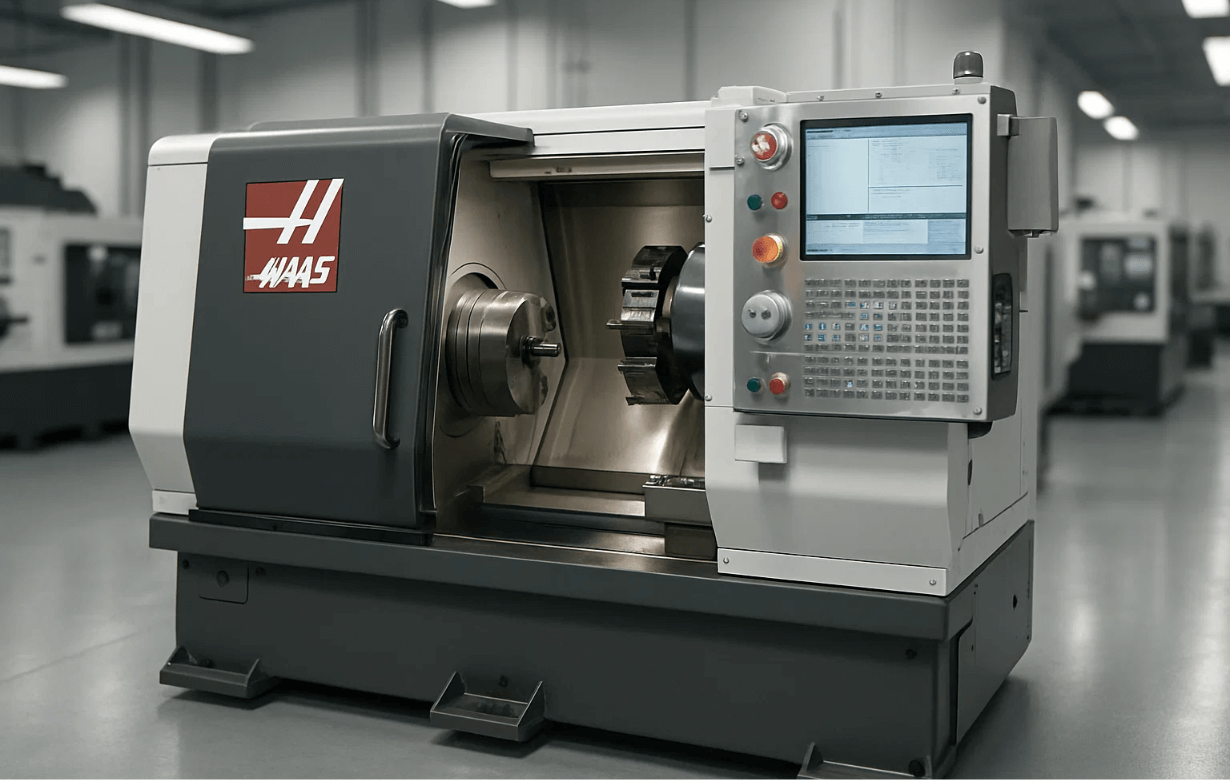

What Makes Haas CNC Lathes a Smart Option?

CNC machines have completely transformed the world of machining and manufacturing, and CNC lathes have played an important role in changing the rules and patterns of manufacturing cylindrical or circular items all around the world. Lathes have made making cylindrical parts much easier and seamless for all the world compared to how it was during the times of manual machining. But among all the CNC brands that make lathes, Haas has built a reputation for being a smart choice. Haas CNC lathes have been able to get the love and appreciation of customers all around for different reasons, like the quality of the machine, the support, and the service that Haas provides to their customers. In this blog, we will discuss all the advantages of buying a Haas CNC lathe and why it is considered a smart option to do so.