Industries

Industries We Serve

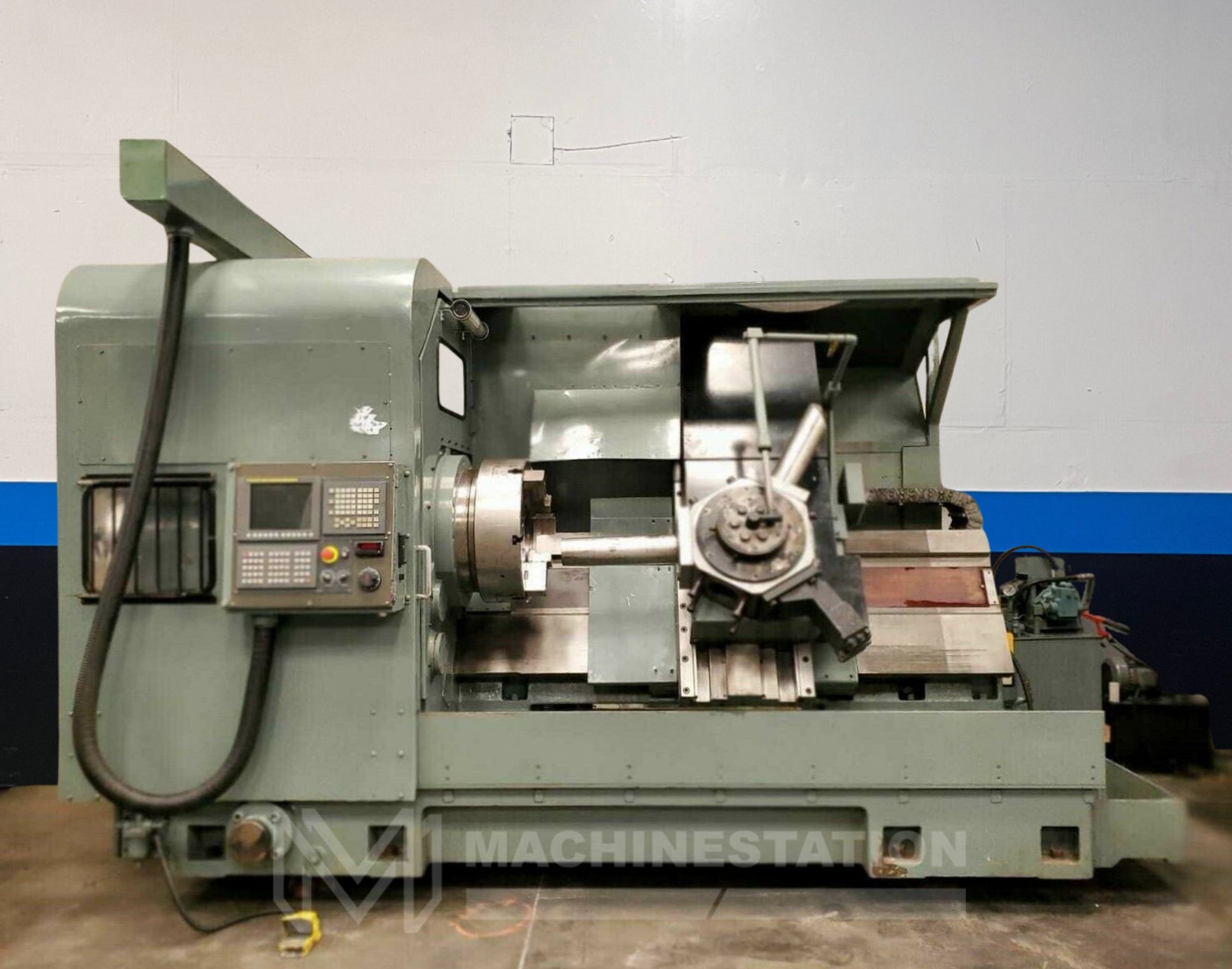

In today’s fast-paced world, precision, speed, and reliability are the cornerstones of manufacturing. And at the heart of it all lies CNC machining. The technology that powers everything from life-saving medical devices to advanced aerospace components, rugged defense equipment, cutting-edge automotive parts, and energy systems that fuel the future.

At MachineStation, your trusted source for high-quality used CNC machines, we’re passionate about equipping businesses with the tools and knowledge to thrive. That’s why we’ve curated a collection of in-depth content exploring the vital role of CNC machining in key sectors. Whether you’re a seasoned engineer or a budding entrepreneur, these resources will ignite your curiosity and arm you with actionable insights.

At MachineStation, your trusted source for high-quality used CNC machines, we’re passionate about equipping businesses with the tools and knowledge to thrive. That’s why we’ve curated a collection of in-depth content exploring the vital role of CNC machining in key sectors. Whether you’re a seasoned engineer or a budding entrepreneur, these resources will ignite your curiosity and arm you with actionable insights.

- Top Dollar Value

- Instant Cash Offers

- Easy Pickup

CNC Machining in the Medical Industry

Precision saves lives. From orthopedic implants to dental tools, medical devices demand micron-level accuracy. Our whitepapers dive deep into:

- How CNC machining enables mass production of safe, reliable, and customized medical components.

- The role of biocompatible materials like titanium and stainless steel.

- Why small-scale manufacturers and startups benefit from investing in CNC technology.

CNC Machining in Aerospace Industry

When safety is non-negotiable, CNC machining steps in. Aerospace and defense rely on components that must endure extreme stress, heat, and pressure. Our resources cover:

- The contribution of CNC machining to turbine blades, engine components, and structural parts.

- How advanced multi-axis CNC machines reduce production times.

- Strict compliance and certification standards that CNC helps manufacturers achieve.

CNC Machining in the Automotive Industry

From high-speed cars to electric vehicles, CNC machining is at the heart of automotive progress. In our whitepapers, you’ll learn:

- Why CNC machining is ideal for both large-scale production and prototyping.

- How it contributes to innovation in EV battery housings and lightweight components.

- The competitive advantage of using used CNC machines for cost-efficient automotive part production.

CNC Machining in the Defense Sector

Defense applications require rugged and precise parts that can’t afford to fail. CNC machining ensures:

- Durable components for vehicles, weapons, and communication systems.

- The future trends in defense manufacturing.

- Faster prototyping for advanced defense technologies.

CNC Machining in the Energy Industry

From renewable energy to oil & gas, CNC machining fuels progress. Our whitepapers highlight:

- The role of CNC machines in producing turbine parts, drilling tools, and heavy-duty components.

- Top practices for CNC machining in the oil and gas industry.

- The long-term cost savings of using CNC in high-demand energy projects.

Here’s a glimpse of what you will discover in our content:

- What materials are used in that industry?

- Why is CNC machining needed for a particular industry?

- What parts of that industry are made using CNC machines?

- What are the major future trends of machining in that industry?

- What are the best practices for machining products in that industry?

Why read, because precision isn’t just a skill, it’s also about the mindset and knowledge. Whether you’re crafting components that push boundaries or scaling your operations with budget-friendly used CNC machines, these industry based resources will encourage you to think bigger, work smarter, and innovate faster.

Ready to elevate your expertise and transform your operations? Our content covers the why, how, and what’s next of CNC machining, offering actionable ideas to drive efficiency and creativity. Don’t just keep up, be the leader of your industry. Click below to explore our free downloads and uncover the strategies that will shape your future in manufacturing. Your journey to precision starts here!

CNC Machining in the Medical Industry

Precision saves lives. From orthopedic implants to dental tools, medical devices demand micron-level accuracy. Our whitepapers dive deep into:

- How CNC machining enables mass production of safe, reliable, and customized medical components.

- The role of biocompatible materials like titanium and stainless steel.

- Why small-scale manufacturers and startups benefit from investing in CNC technology.

CNC Machining in Aerospace Industry

When safety is non-negotiable, CNC machining steps in. Aerospace and defense rely on components that must endure extreme stress, heat, and pressure. Our resources cover:

- The contribution of CNC machining to turbine blades, engine components, and structural parts.

- How advanced multi-axis CNC machines reduce production times.

- Strict compliance and certification standards that CNC helps manufacturers achieve.

CNC Machining in the Automotive Industry

From high-speed cars to electric vehicles, CNC machining is at the heart of automotive progress. In our whitepapers, you’ll learn:

- Why CNC machining is ideal for both large-scale production and prototyping.

- How it contributes to innovation in EV battery housings and lightweight components.

- The competitive advantage of using used CNC machines for cost-efficient automotive part production.

CNC Machining in the Defense Sector

Defense applications require rugged and precise parts that can’t afford to fail. CNC machining ensures:

- Durable components for vehicles, weapons, and communication systems.

- The future trends in defense manufacturing.

- Faster prototyping for advanced defense technologies.

CNC Machining in the Energy Industry

From renewable energy to oil & gas, CNC machining fuels progress. Our whitepapers highlight:

- The role of CNC machines in producing turbine parts, drilling tools, and heavy-duty components.

- Top practices for CNC machining in the oil and gas industry.

- The long-term cost savings of using CNC in high-demand energy projects.

Here’s a glimpse of what you will discover in our content:

- What materials are used in that industry?

- Why is CNC machining needed for a particular industry?

- What parts of that industry are made using CNC machines?

- What are the major future trends of machining in that industry?

- What are the best practices for machining products in that industry?

Why read, because precision isn’t just a skill, it’s also about the mindset and knowledge. Whether you’re crafting components that push boundaries or scaling your operations with budget-friendly used CNC machines, these industry based resources will encourage you to think bigger, work smarter, and innovate faster.

Ready to elevate your expertise and transform your operations? Our content covers the why, how, and what’s next of CNC machining, offering actionable ideas to drive efficiency and creativity. Don’t just keep up, be the leader of your industry. Click below to explore our free downloads and uncover the strategies that will shape your future in manufacturing. Your journey to precision starts here!

New Arrivals