*All specifications are approximations and are subject to verification. Comes as shown in the images. Please call us if you have any questions before making a purchase. All sales are final.*

| Make: | Matsuura |

| Model: | H.Plus-300 |

| Year: | 2007 |

| Machine Type: | Horizontal Machining Center (HMC) |

| Condition: | Used – Good |

| Equipped With: |

|---|

- Twin Pallet Automatic Pallet Changer (PC2)

- BT40 Spindle Taper

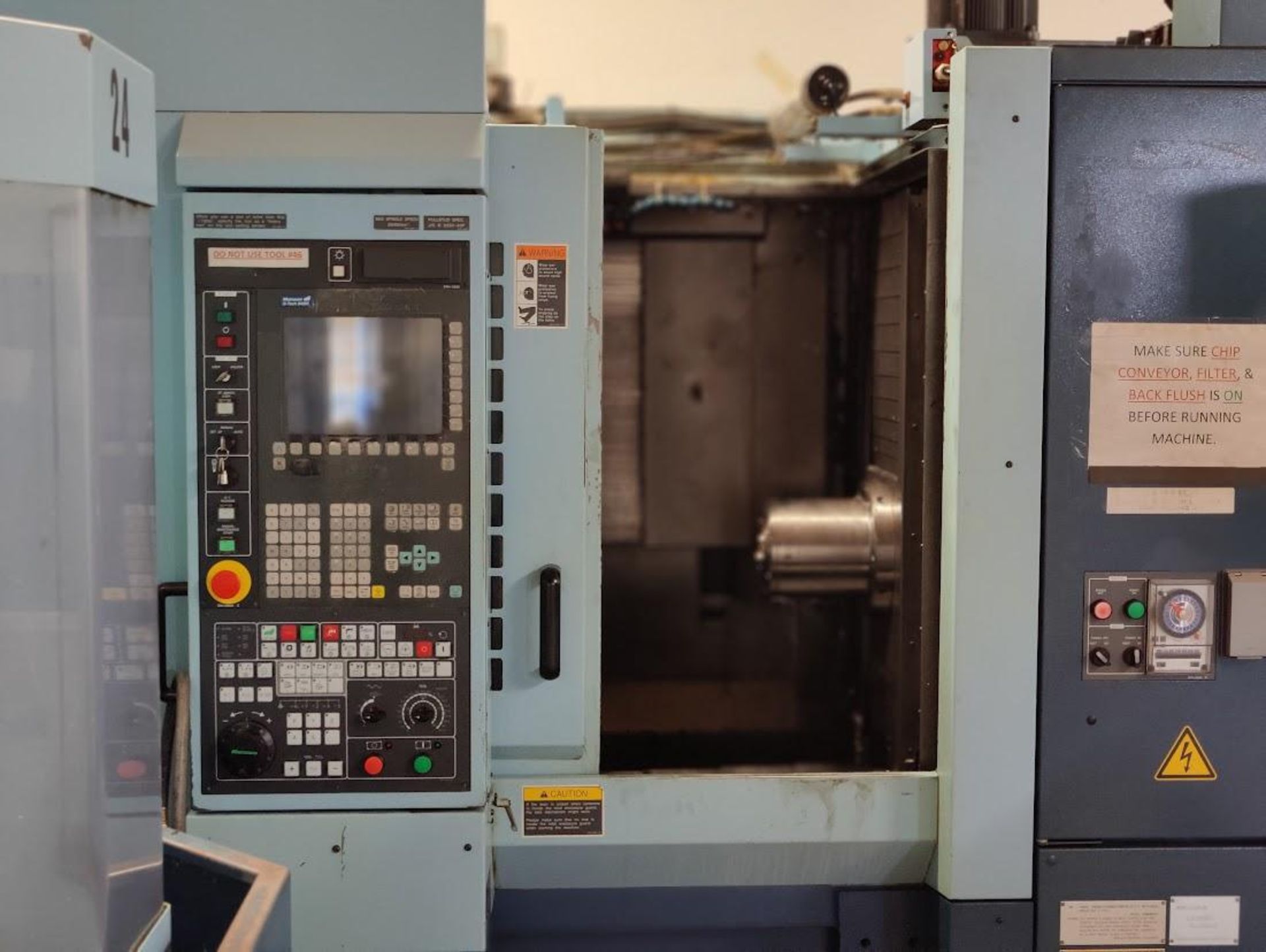

- Matsuura G-Tech 30i CNC Control

- 60-Tool Automatic Tool Changer

- Flood Coolant System

- Total Enclosure with Ceiling

- Spindle Oil Cooler

- Automatic Grease Lubrication (Spindle & Axes)

- Work Light

- Safety Interlocks

|

| Travels & Axes: |

|---|

- X-Axis Travel: 19.68″

- Y-Axis Travel: 22.04″

- Z-Axis Travel: 19.68″

- B-Axis: 360° Continuous Indexing

- Min. Distance from Pallet Center to Spindle Gauge Line: 2.76″

|

| Feedrates & Dynamics: |

|---|

- Rapid Traverse X/Y/Z: 2,362 IPM

- Rapid Acceleration (X/Y/Z): 0.93 / 1.28 / 1.06 G

|

| Pallet & Work Capacity: |

|---|

- Pallet Size: 11.81″ × 11.81″

- Max Pallet Load: 551 lbs

- Max Workpiece Envelope: Ø20.86″ × 29.92″ H

- Pallet Change Time: 6.6 sec (Pallet-to-Pallet)

- APC Type: Rotary Twin-Pallet Changer

- Optional Pallet Systems: PC5 / PC11 Floor, PC15 Tower (Up to 15 Pallets)

|

| Spindle: |

|---|

- Spindle Speed Range: 50 – 15,000 RPM

- Spindle Motor Power: 20 HP

- Max Torque: Approx. 88 lb-ft @ 1,200 RPM

- Integrated Spindle Grease Auto-Lubrication

- Spindle Noise Level: < 75 dB

- In-House Built Spindle (Matsuura – Japan/UK)

- Optional Spindles: 20,000 RPM / 30,000 RPM

|

| Automatic Tool Changer: |

|---|

- Standard Tool Capacity: 60 Tools

- Tool-to-Tool Time (Chip-to-Chip): 2.4 sec

- Max Tool Weight: 17.6 lbs

- Max Tool Length: 11.81″

- Max Tool Diameter: 3.15″ (5.91″ Adjacent Pocket Empty)

- Optional Tool Magazines: 120 / 150 / 180 / 210 / 240 / 320 Tools

|

| CNC Control: |

|---|

- Matsuura G-Tech 30i CNC Control

- 10.4″ Color LCD

- Nano Interpolation

- High-Speed CPU with Optical FSSB Bus

- Look-Ahead: 200 Blocks (Up to 1,000 Optional)

- Compact Flash & PC File Handling

|

| Accuracy & Thermal Control: |

|---|

- THERMAL MEISTER™ Thermal Compensation System

- Spindle & Axis Thermal Displacement Compensation

- Optional Heidenhain Linear Scales (X/Y/Z)

- Nanometer Positioning Resolution

|

| Coolant & Chip Management: |

|---|

- Flood Coolant System

- Swarf Rear Discharge

- W-Type Z-Axis Cover

- X-Type APC Door for Chip Splash Reduction

- Optional Through-Spindle Coolant (290 / 725 / 1,015 PSI)

- Optional Chip Conveyors (Spiral / Lift-Up / Scraper)

- Optional Mist Collector

|

| Electrical: |

|---|

- Power Requirement: 42 kVA

- Voltage: AC 200 / 220V ±10%

- Frequency: 50 / 60 Hz

- Air Pressure: 78 – 135 PSI

- Air Consumption: ≤ 12.4 CFM

|

| General: |

|---|

- Machine Weight (Approx.): 18,300 lbs

- Compact Footprint (~15% Smaller than Prior H.Plus Generation)

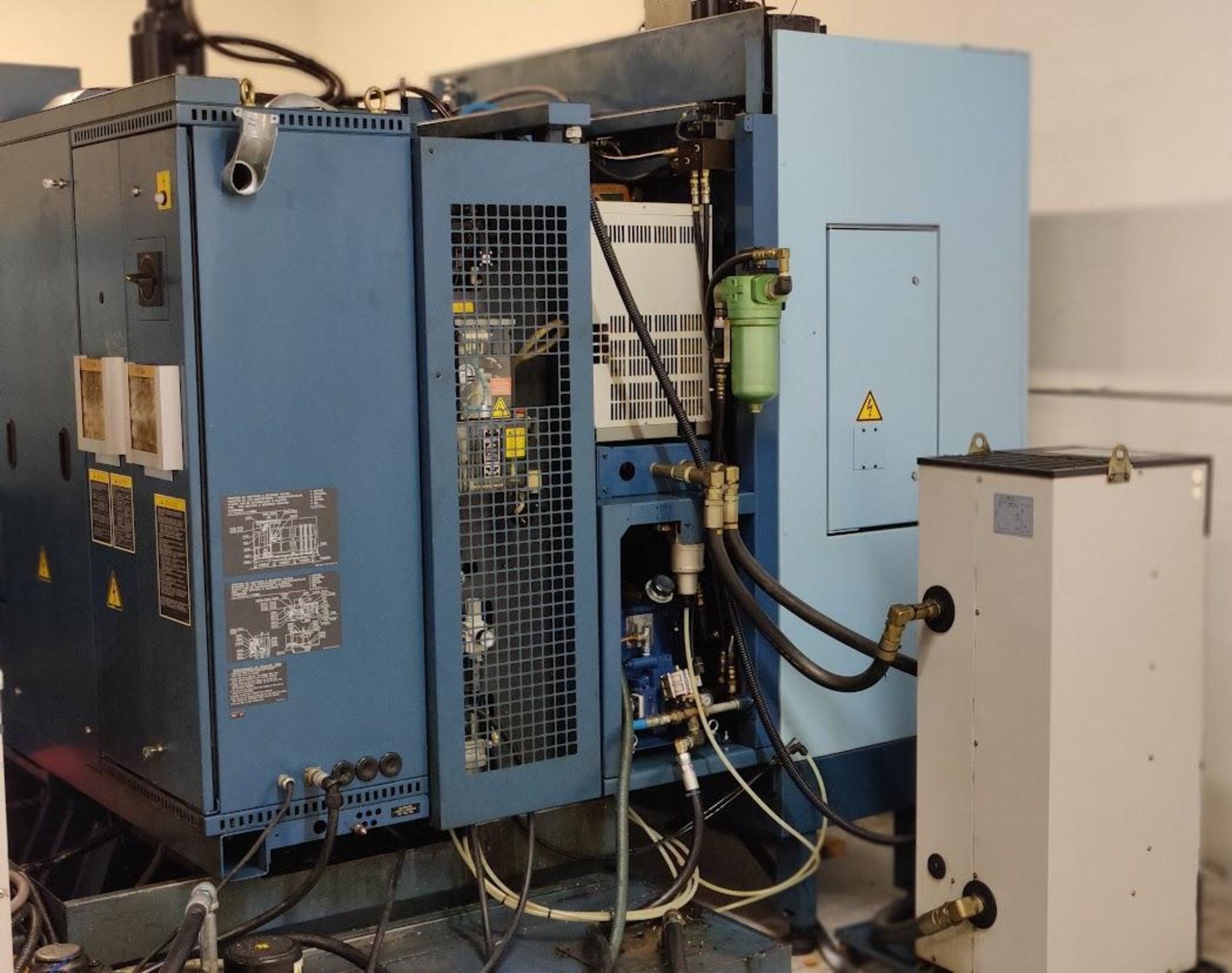

- Rear-Service Maintenance Layout

|