*All specifications are approximations and are subject to verification. Comes as shown in the images. Please call us if you have any questions before making a purchase. All sales are final.*

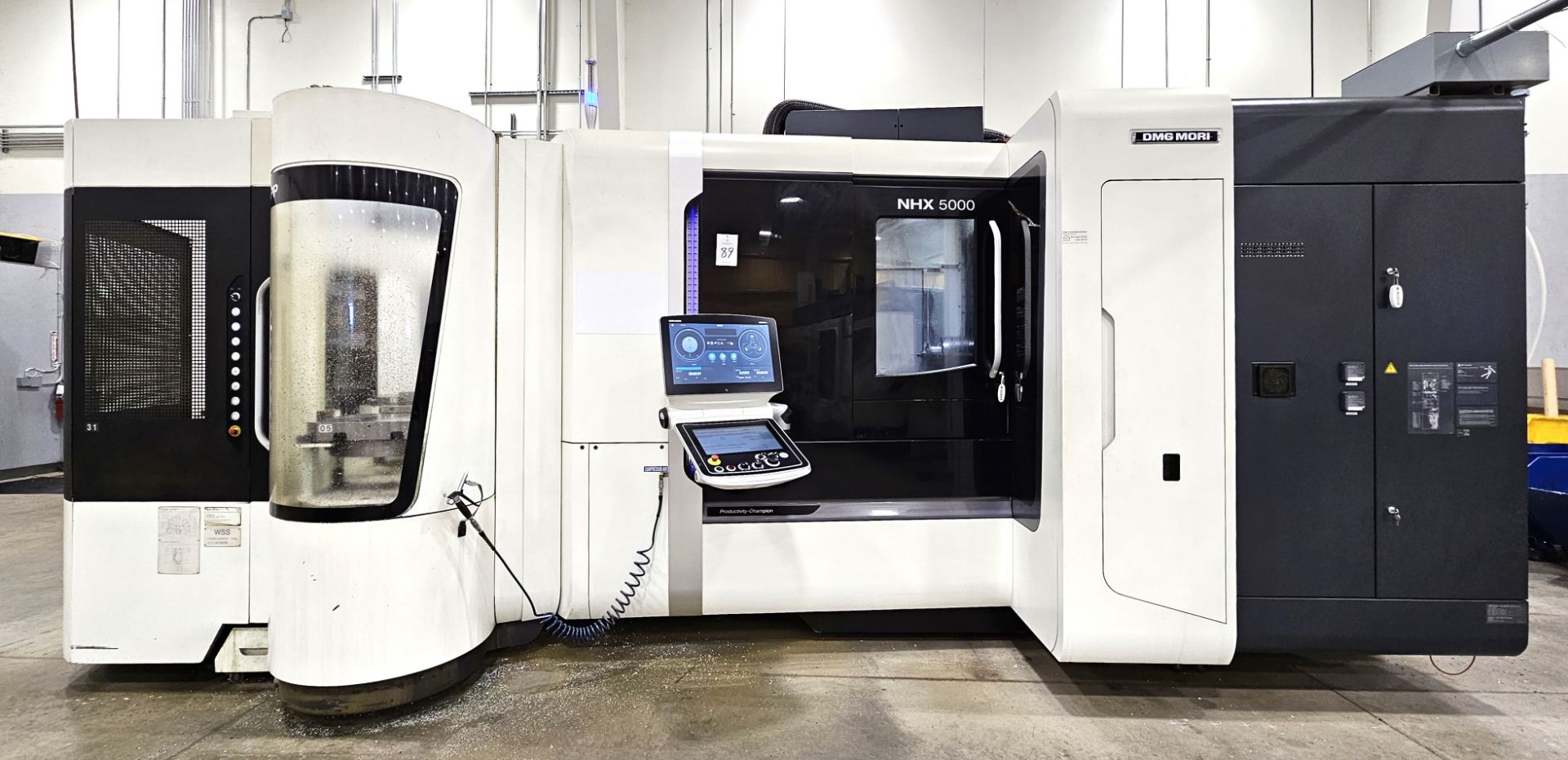

| Make: | DMG Mori |

| Model: | NHX 5000 Gen 2 |

| Year: | 2018 |

| Condition: | Used – Good |

| Machine Type: | CNC Horizontal Machining Center |

| Country of Origin: | Japan |

| Equipped With: |

|---|

- Full 4th Axis Rotary Table (B-Axis)

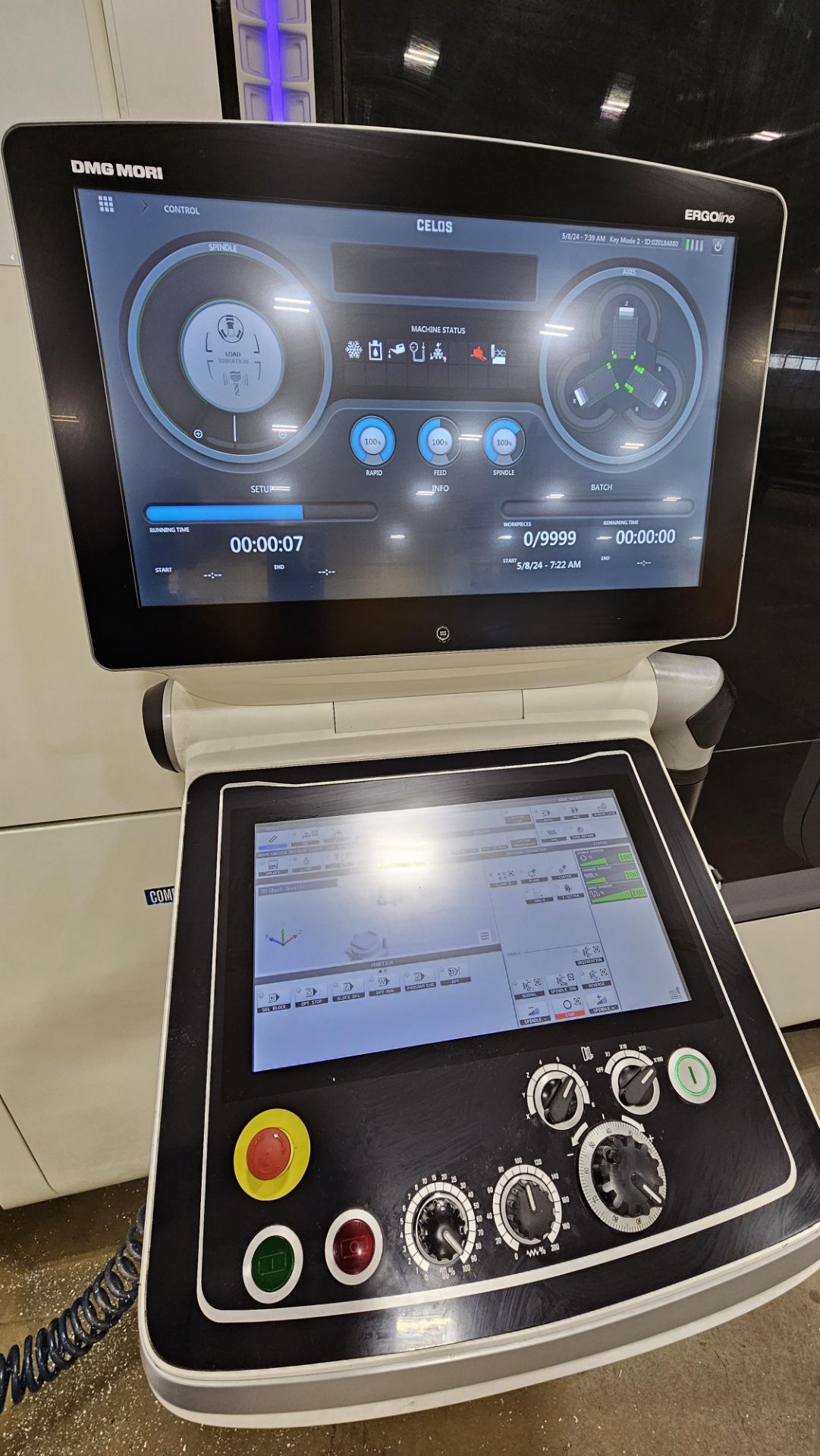

- DMG Mori CELOS with MAPPS CNC Control (Mitsubishi-based)

- High-Torque BT50 Spindle

- Automatic Tool Changer

- Rigid Tapping

- Thermal Stability Control

- Spindle Chiller

- Coolant System

- High-Pressure Coolant Ready (Option Dependent)

- Chip Conveyor

- Automatic Central Lubrication

- Fully Enclosed Guarding

- Hydraulic System

- Work Light

|

| Travels: |

|---|

- X-Axis Travel: 40.2″ (1,020 mm)

- Y-Axis Travel: 24.0″ (610 mm)

- Z-Axis Travel: 26.0″ (660 mm)

- B-Axis Rotation: 360° Continuous

- Rapid Traverse (X / Y / Z): Approx. 1,650 IPM

|

| Pallet & Table: |

|---|

- Pallet Size: 19.7″ × 19.7″ (500 × 500 mm)

- Maximum Pallet Load: 1,100 lbs (500 kg)

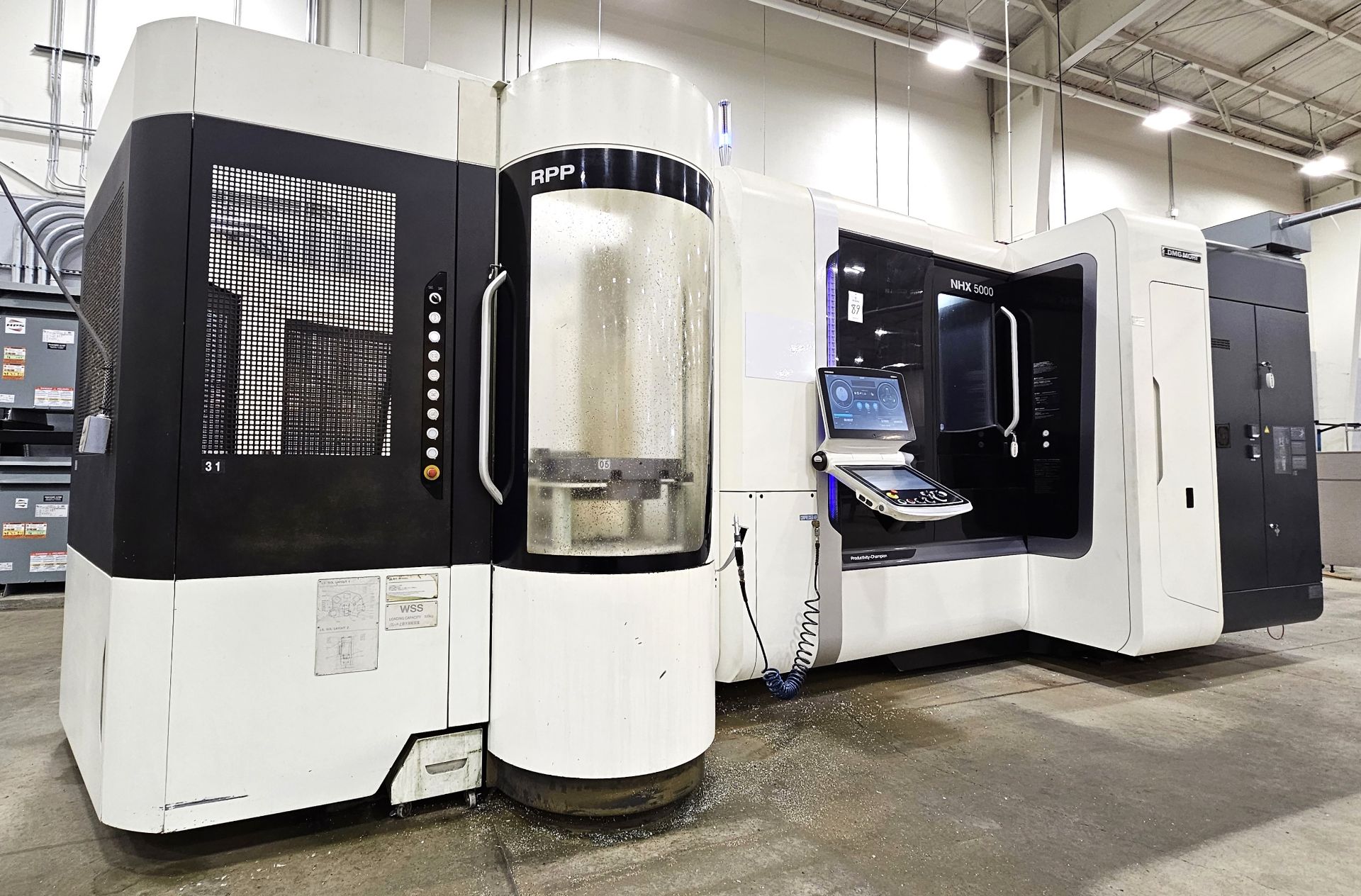

- Twin Pallet Shuttle System

- Automatic Pallet Indexing (Full 4th Axis)

|

| Spindle: |

|---|

- Spindle Taper: BT50

- Maximum Spindle Speed: 12,000 RPM (15,000 RPM Optional)

- Spindle Motor Power: Approx. 50 HP (37 kW)

- High-Torque Direct-Drive Spindle

- Oil-Air Lubrication

|

| Automatic Tool Changer: |

|---|

- Tool Capacity: 60 Tools (120 Tools Optional)

- Tool-to-Tool Time: Approx. 2.5 – 3.5 Seconds

- Maximum Tool Length: Approx. 12″

- Maximum Tool Weight: Approx. 44 lbs

|

| Feedrates: |

|---|

- Rapid Traverse (X / Y / Z): Approx. 1,650 IPM

- High-Precision Servo-Controlled Cutting Feedrates

|

| Electrical: |

|---|

- Power Requirement: 400 – 480V / 3-Phase / 50 – 60 Hz

- Power Capacity: Approx. 45 – 55 kVA

- Air Requirement: Approx. 70 – 90 PSI

|

| General: |

|---|

- Overall Dimensions (Approx.): 165″ × 120″ × 118″

- Machine Weight (Approx.): 26,000 – 33,000 lbs

|

| Notes: |

|---|

- Specifications based on NHX 5000 Gen 2 standard configuration

- Machine equipped with a full 4th-axis rotary pallet system as shown

- Options and exact specifications may vary by build

|