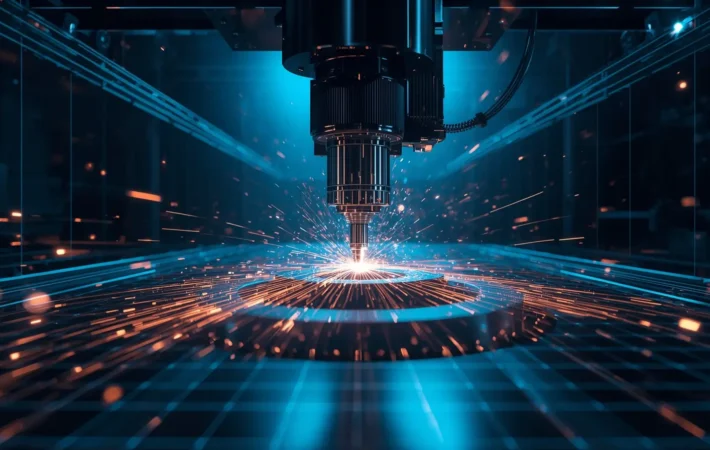

How Small CNC Shops Can Compete with Large Manufacturers?

Manufacturing has always been a tough sector to enter for startup founders and small business owners. Manufacturing needs more upfront capital investment, which makes it harder for small shops to compete with large manufacturers with high capital investment capability. But that doesn’t make it impossible for small shops to grow and win; it can very well be done if the right steps are taken. If you are also running a small CNC shop or just starting up, then read this blog till the end to know how small CNC shops competing with large manufacturers can win.