Automotive

Table of Contents

- All About Automotive CNC Machining

- What is Automotive CNC machining?

- How does CNC machining help the automotive industry?

- What are the types of CNC machines used for automotive manufacturing?

- Top Automotive Parts that are Manufactured using CNC Machining

- Key Trends in the Future of Automotive CNC Machining

- Limitations of CNC Machining in the Automotive Sector

- Top Practices for Manufacturing Automotive Parts using CNC Machine

- Top Automotive Parts and their required CNC Models

- Conclusion

Quick Contact

All About Automotive CNC Machining

According to a report, the Automotive parts manufacturing market size is estimated to be $ 2.25 trillion in 2024, and the market is expected to reach $ 2.761 trillion approximately by 2033, growing at a CAGR of 2.3%.

The automotive industry is one of the most critical industries in terms of manufacturing design and precision needs. The industry requires machining of a wide range of products, from small to large in size, and with various intricate designs. Those designs cannot be easily achieved with traditional machining processes. For that reason, CNC machining is becoming increasingly important for automotive machining companies.

Automotive manufacturing is also evolving to be more advanced with time. Modern EVs utilise different materials compared to cars that run on fossil fuels. Also, new designs of cars are being introduced by top end brands such as Pagani or Bugatti, which need modern advanced machines that can develop those parts with intricate design while maintaining tight tolerances.

So, the industry is very much dependent on CNC technology. If you’re someone who is planning to enter this industry or learn about it, then you have reached the best page on the internet. Let’s dive into it.

What is Automotive CNC machining?

Automotive CNC machining is the process of machining different automotive parts, which can be anything from cylinder heads to brackets, and are made with the help of different CNC machines. Different materials are used to make automotive parts, and several types of CNC machines can be used to manufacture those parts. The same goes for the tolerance limits needed for the parts, and that can be done using different types of machines like mills, lathes, routers, or grinders, and also the number of axes of that machine.

How does CNC machining help the automotive industry?

Here’s how CNC machining can help the automotive industry in the manufacturing of different kinds of parts of different materials:

- Unmatched precision: Automotive is a very critical sector because it needs parts that can fit properly or work under tight performance conditions. So, a high level of precision is essential for that. A deviation of even a millimeter can cause total damage to the design or the functioning of the machine in total. So high level of precision is a non-negotiable factor for automotive machining.

- Complexity of parts: Some parts used in the automotive sector are extremely hard to manufacture using traditional machining methods. Multi axis CNC machines can get those parts with complex geometries designed in a very short time, in just one setup, without the need for human intervention. CNC machines can easily make an intricate design on a raw workpiece by machining it from multiple sides.

- Superior repeatability: One of the most important metrics that you need to take care of when doing high volume machining production is repeatability. The machine should be able to do constant high-volume production while maintaining accuracy and tolerance.

- Versatility across materials: CNC machining is also great for machining different materials. Several tough or sensitive materials are hard to machine using traditional machining methods, and need high end CNC machines of top brands for proper manufacturing without breaking the tolerance limits or destroying the raw workpiece by any means.

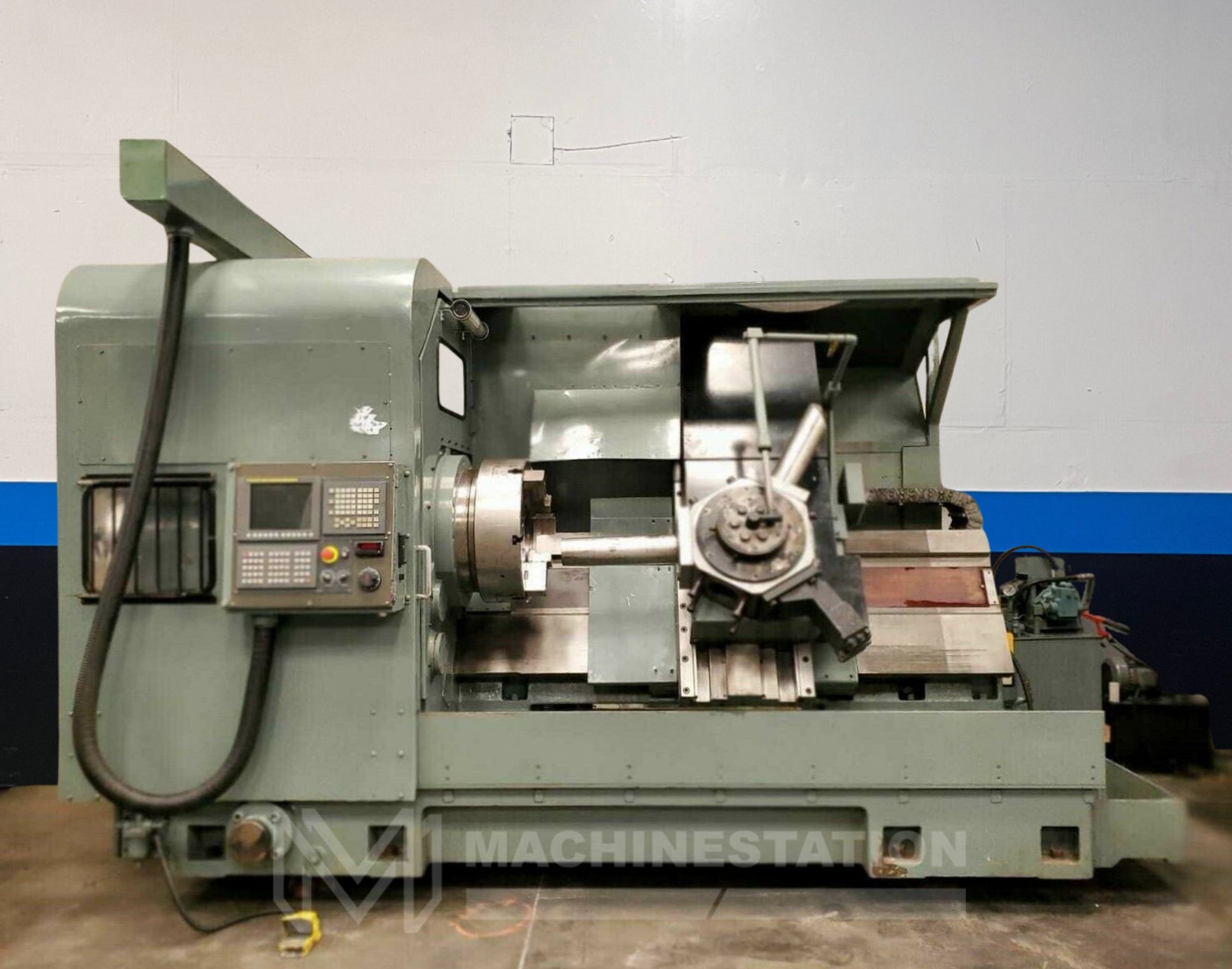

What are the types of CNC machines used for automotive manufacturing?

Here are some major types of CNC machines that are used for different types of automotive machining experience:

- CNC milling machines: Milling machines use a moving tool to cut materials from a stationary workpiece and give it the needed shape. These machines often come with multiple axes, making them a versatile choice for making products of different kinds of geometries. You can have different kinds of milling machines, like 3-axis, 5-axis, or even 7-axis milling machines. The number of axes of your CNC machine should be decided upon the fact of what level of critical geometric shape you’re working on. These machines are used for different parts like chassis, engine blocks, chassis heads, manifolds, etc.

- CNC lathes: In these machines, the cutting tool stays at one position while the workpiece moves around it and gets into your required shape. They are mainly used to make cylindrical parts or parts of oval shapes. They can be used for manufacturing parts like shafts, pistons, bearings, axles, and crankshafts. But some lathes in modern times also have features of milling machines, which help the machinists to do both milling and turning operations in the same machine, eventually saving a lot of cost.

- CNC grinding machines: The grinding machines are used to give a polished look to the materials. They use an abrasive wheel to achieve an extremely fine level of finishing and give top level dimensional accuracy on hardened materials. There can be two types of grinding, one is cylindrical grinding, which is used to provide finishing to the outer surface of the cylindrical parts, and surface grinding is employed for making flat and parallel surfaces.

- CNC drilling machines: CNC drilling machines are used for high precision hole making in different components like transmission cases. Their major advantage is the multiple spindle options. They also help in speeding up the machining process by ensuring perfect alignment of tools. CNC drilling machines are used for making parts like gearboxes, engines, and body panel mounting.

- CNC waterjet/plasma/laser cutters: These are three unique machines that are also employed in the automotive industry for different purposes. The waterjet cutters can cut any workpiece without letting any thermal decomposition take place, the plasma cutters are used for seamless machining of tough materials, and the laser cutters are used for high speed cutting with a minimal amount of waste generated.

Top Automotive Parts that are Manufactured using CNC Machining

Here are some of the major parts of the automotive sector that can be machined using CNC machining:

- Engine blocks: The most important and critical parts that are manufactured using CNC machines in the aerospace sector are the engine blocks and parts. CNC machines ensure precise combustion chambers, which help in improving the fuel efficiency of the machines. Different parts of the engine, like blocks, pistons, camshafts, and cylinder heads, are made using CNC machines.

- Transmission and drive train components: Gear teeth need high precision machining, and that can be done using multi-axis CNC machines. Internal splines on gears and shafts are also made using CNC machines, and they are essential in automobiles for smoother transmission of power. The complex castings of transmission housings are also made using CNC machines. The axles and driveshafts are made using the lathes and milling machines to give them the right shape.

- Body, interior, and electronic parts: Several small parts needed for the proper functioning of automobiles are made with the help of CNC machines. CNC machines are very important for creating different injection molds that are used to mass produce plastic components like dashboards, interior trims, and bumpers. The intricate shapes of the lights are also often machined using CNC machines.

- Chassis and suspension components: These structural parts of the automobiles are made with the help of a CNC machine. They are often machined from materials like aluminium and steel blocks, which helps them to achieve a high strength-to-width ratio. CNC machines are also used to make brake calipers and turn brake discs to ensure a perfectly flat and parallel braking surface.

Key Trends in the Future of Automotive CNC Machining:

Here are some of the major emerging trends in the world of automotive CNC machining:

- Automation and robotics: The whole machining world is on the verge of being totally automated and won’t need any human intervention. AI-powered CNC systems can automate tool path optimization. The robotic arms of the CNC machines help in the automated loading and unloading of the materials. Also, the factory floors are getting optimized with the help of automated guided vehicles that move the materials all around the floor.

- More multi-axis and hybrid machines: The demand for multi axis machines is increasing in sectors like automotive, where precision machining is super important. More innovations are being done. More complex geometrical parts are being used. For that, more multi axis machines are also being used, like 5-axis, 7-axis, and 12-axis. Also, hybrid machines are being adopted at a very high rate by the automotive manufacturing sector for total machining work in one setup.

- IoT and Industry 4.0: The integration of IoT with CNC machines has changed the machining standard. Machines are now equipped with sensors that can collect real time performance data, tool wear, and other production metrics. The machine operators can now see the machining status on a digital dashboard.

- Sustainability: The whole world is moving towards more green and sustainable manufacturing. Machinists are now looking for CNC machines that are more energy efficient. They are also looking for the recycling of materials for more sustainable manufacturing.

Limitations of CNC Machining in the Automotive Sector:

Here are some of the limitations of CNC machining in the automotive industry:- Higher initial investment: Getting into the automotive industry is not an easy thing. It needs a huge initial investment. The CNC machines that can do these high precision machining jobs are costly, and you will have to buy them to get good results. So, as a beginner or mid sized business owner, you must make a strategic financial investment. You can go ahead with buying used CNC machines to save money on upfront investment.

- Lack of skilled talent: There is a huge demand for machining talents all around the world, but there is also a big lack of skilled machine operators. To hire the highly qualified talent, you will need to break the bank. So, the solution can be hiring a newbie operator and giving them the essential training to make sure they become the skilled operators who can manage those high end CNC machines.

- Advanced softwares utilization: Advanced softwares can actually help you to generate a great toolpath, which will ensure a safe machining experience. These softwares help by streamlining the design to production workflows, optimizing the toolpath, and creating simulations which will help in the detection and minimizing of errors.

Top Practices for Manufacturing Automotive Parts using CNC Machine:

Here are some of the major recommendations from our side about best practices to follow while machining automotive parts using CNC machines:- Designing and planning: Designing and planning beforehand are as important as carrying out the task in the proper way. With that, you can minimize the probability of any kind of clashes during the machining work, and you will be able to prolong the life of the cutting tool of your machine.

- Material selection and tooling: Both of them need to match each other. Make sure you are choosing the right tool for the right material. Also, the machine model is important because not all models can handle heavy materials.

- Process optimization: Don’t try to manage the whole machining process and try to optimize and automate most jobs. Make sure to get most jobs done in one setup, and then change it for the next one. Document all the parameters to make sure that you don’t make one mistake twice.

Top Automotive Parts and their required CNC Models:

Here are some of the major automotive parts that can be machined using CNC machine, and the machine models that you might use:

- Engine Block: Makino a92

- Gear Shaft: Mazak INTEGREX i-200

- Transmission Gear: Liebherr LC 300

- Clutch Housing: Makino a61nx

- Flywheel: Okuma LB3000 EX II

- Brake Caliper: Makino a51nx

- Brake Rotor: Okuma LU3000 EX

- Suspension Link: DMG MORI DMU 65 monoBLOCK

- Fuel Injector: Citizen Cincom L32

- Fuel Rail: Star SR-38 Type B

- Pump Housing: Makino a61nx

- Shock Absorber Mount: Haas VF-2SS

- Steering Knuckle: Mazak HCN-5000

- Ball Joint: Citizen Cincom L32

- Control Arm: DMG MORI DMU 65 monoBLOCK

- Chassis Bracket: Mazak HCN-5000

- Heat Exchanger: Makino MAG3

- Axle Hub: Okuma LB3000 EX II

- Radiator Support: Haas EC-400

- Wheel Spacer: Doosan Puma GT2100

- Cylinder Head: Makino a92

- Piston: DMG MORI NLX 2500SY

- Crankshaft: Mazak INTEGREX e-670H

- Camshaft: Okuma MULTUS U4000

- Intake Manifold: Haas UMC-750

- Exhaust Manifold: DMG MORI DMU 65 monoBLOCK

- Valve Cover: Makino a51nx

- Timing Cover: Haas VF-4SS

- Connecting Rod: Mazak INTEGREX i-200

- Turbocharger Housing: Okuma MU-5000V

Conclusion:

Automotive is a very tough category of manufacturing. They need several complex engineering parts that need to perform right all the time or it may cause major accidents and life loss. So, we would suggest that you get the best machines for the job, and choose used machines from our site so you can get them without breaking the bank.

New Arrivals