Defense

- All about CNC Defense Manufacturing

- Introduction to CNC defense manufacturing

- Key characteristics that define the defense manufacturing sector

- What Materials are used in machining with CNC Machines for Defense Manufacturing?

- Which CNC Machines are used for Defense CNC Manufacturing?

- Defence Parts that are made using CNC Machines

- Challenges in Defense CNC Machining

- Top Practices to Follow for Defense Manufacturing using CNC Machines

- Top Future Trends in Defense Manufacturing

- Top machine models used for manufacturing defense parts

- Conclusion

Quick Contact

All about CNC Defense Manufacturing

Introduction to CNC defense manufacturing:

Defense manufacturing is a very demanding and critical manufacturing sector that needs manufacturing of minute parts like the bolts used in different to the large wing ribs of the fighter jets. This industry is one of the finest engineering sectors in the world.

The whole defense manufacturing sector works at the intersection of uncompromising quality, extreme precision, and national security. The industry needs to make products that can withstand harsh conditions and do the right job with top precision under extreme conditions.

Key characteristics that define the defense manufacturing sector:

Here are some of the major characteristics that shape the whole defence manufacturing industry:- Exceptional precision: Defence manufacturing is a high precision sector that needs equipment with extremely tight tolerances, and critical geometries that non negotiable. In this industry, tolerances as high as ±0.0001 inches are routine.

- Part complexity: The naval products and aerodynamics parts are parts that have extremely critical designs that cannot be achieved without the utilisation of high end CNC machines.

- Material versatility: Different kinds of materials are used to make defense equipment using CNC machines. Materials like titanium and other advanced composites are used in the defense manufacturing industry, and they cannot be machined without using highly powerful CNC machines.

What Materials are used in machining with CNC Machines for Defense Manufacturing?

Here are some of the materials that are used for making defence products with the help of CNC machines:- Titanium alloys: Titanium alloys are one of the most commonly used materials in the defence manufacturing business. They are known to be corrosion resistant and for their exceptional strength-to-width ratio. These materials provide superior strength and toughness for different components. Different types of titanium alloys that are used in this industry include Ti-6Al-4V, Ti-6Al-2Sn-4Zr-2Mo, and Ti-3Al-2.5V.

- Aluminium alloys: This is highly important for lightweight structural components. They have excellent machinability, and also have a great corrosion resistance feature which is great for aircraft structures. The 6061-T6 aluminum is one of the most commonly used aluminium alloy for defense product machining, as it also has high thermal conductivity.

- Inconel and superalloys: These nickel based alloys are one of the best materials that are used for defence manufacturing. These materials are exceptionally strong, and they can retain their properties even at an extremely high temperature. These materials are used for making crucial engine parts that need to withstand extremely high temperatures.

- Advanced composite: Different advanced composite materials are used for defense manufacturing works. Materials like Carbon Fiber Reinforced Polymers (CFRPs) are being used by defence companies to ensure the weight while the strength remains high.

Which CNC Machines are used for Defense CNC Manufacturing?

Here are some of the main types of CNC machines used for defense manufacturing works:- Multi axis mills: Multi axis mills are one of the most important types of CNC machines that are used for making parts with intricate geometries. The complex structures can be made with it because these machines can approach the workpiece from multiple angles. They can get the most complex of designs done in a single setup.

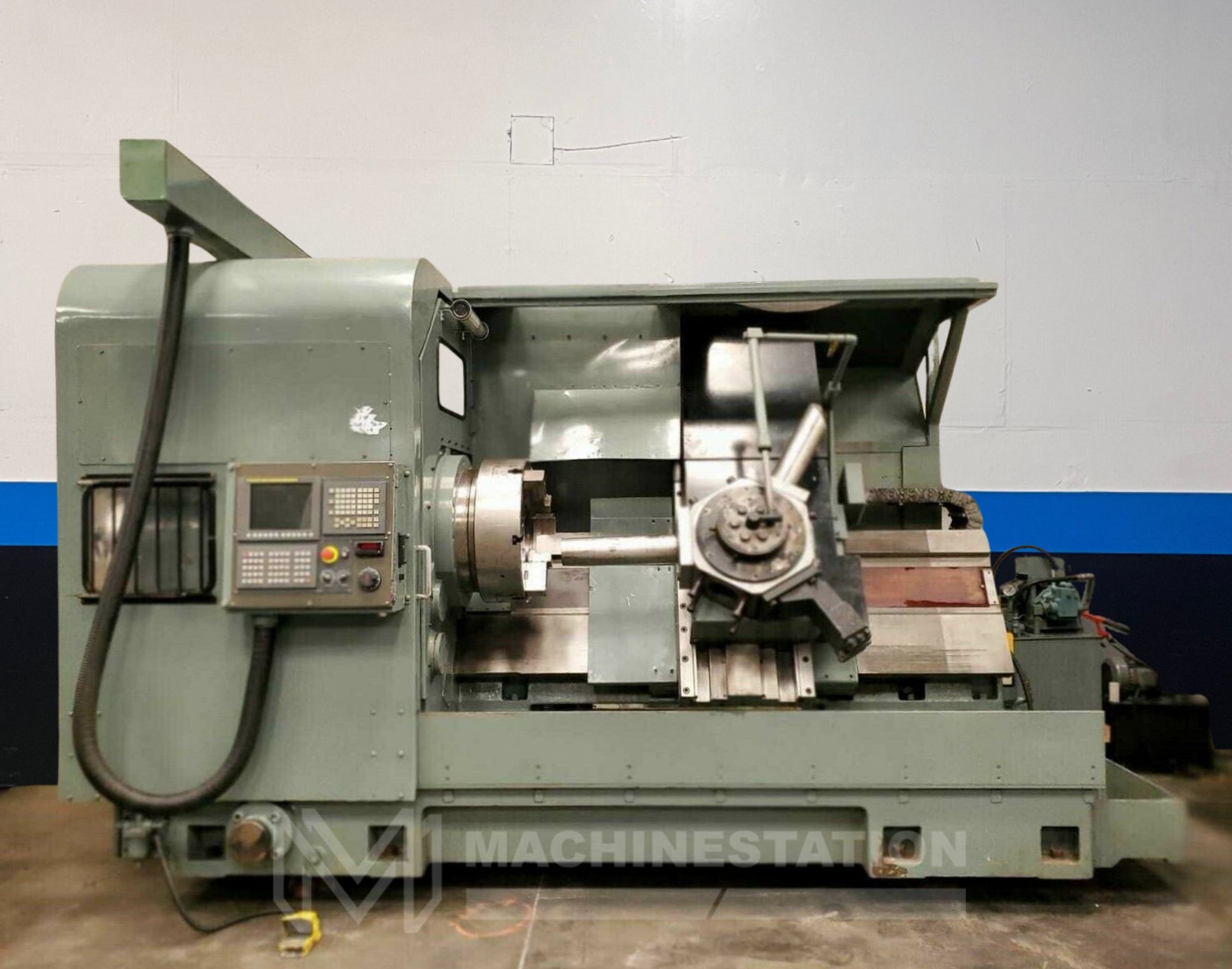

- Lathes: These machines can do the manufacturing of products that are cylindrical in shape. These machines are the best for producing products like shafts and valve bodies that form the foundation of military equipment.

- CNC grinders: All the defence products need a superior surface finish, which can be achieved with the help of these CNC grinding machines. The parts or products that have micro finish requirements are made with these CNC machines.

- Swiss machining systems: These machining systems specialize in the production of small and high-precision components, while maintaining high tolerance limits. These machines are very important for manufacturing precision fasteners and modern sensor components.

- CNC EDMs: EDMs are Electrical Discharge Machining CNCs. They are used for cutting harder materials and give them an intricate design. This is ideal for manufacturing precision weapon components and molds.

Defence Parts that are made using CNC Machines:

Here are some defence parts that are made using different CNC machines:- Structural components: Structural components in the defense sector include several things, like the wing spars, structural bulkheads, propellers and shafts for ships, and tank hulls. These parts are for ensuring that the structural integrity of the aircraft, ships, and tanks is well maintained.

- Engine components: Engine components of different defence vehicles, like aircraft, ships, and other armoured vehicles, are made with the help of CNC machines. Manufacturing engine components is one of the most demanding CNC applications. Engine casings, turbine blades of jets, and gearbox housings of ships are made with the help of CNC machines.

- Other components: Different types of defense products are made using CNC machines, like landing gear components, receivers and barrels of firearms, missile fins, and submarine parts like propulsion and sonar systems, are made with the help of CNC machines.

Challenges in Defense CNC Machining:

Here are some main problems that someone faces during defence manufacturing with CNC machines:- High costs: Defense sector products need high end materials that also cost very high, and the machines that do the manufacturing jobs are also of high end brands, which come at a very high price range.

- Skill shortages: The products of the defense sector are not easy to manufacture as they have critical geometries and intricate designs. Highly skilled workers are needed for doing those engineering jobs, and it is not so easy to find those talents.

- Regulatory compliance: Safety standards are very high in the defense sector; one small mistake in those products can cause catastrophic damage. There are high regulatory standards for these products in all countries, which makes it harder to manufacture and sell these products.

- Technological gaps: The industry evolves at an extremely rapid pace, so it becomes very hard for small companies to catch up with that. You need to put on lots of upfront investment to make sure that you can catch up with high end technological advancements that are happening.

Top Practices to Follow for Defense Manufacturing using CNC Machines:

Here are some tips that you need to keep in mind while getting into the defense manufacturing industry:- Tool management: Tool management is one of the most critical things that you need to get right, for sure. Like you need to have carbide tools with the right coatings can help you extend the tool life while machining harder materials. High performance coatings like the TiAIN help in providing thermal protection and wear resistance. Other than that, regular tool condition monitoring is also very important.

- Setup optimization: To design or manufacture complex geometrical parts, one needs to focus on setup optimization, too. Modular fixturing systems help in accommodating various part geometries. The zero-point clamping system also enables rapid changeover between jobs, and custom fixtures give rigidity for specific applications.

- Quality control and inspection: Quality production is very important for the defense manufacturing sector. Probe based measurement systems help in verifying dimensions without removing parts, and real time monitoring of cutting forces and vibration detects problems early.

- Safety and environmental considerations: Different safety standards are also required to be followed in defense manufacturing shops. Machine guarding helps in preventing access to dangerous areas during the whole operation, also emergency procedures ensure rapid response to the incidents. Also, make sure to conduct chip and waste disposal following appropriate regulations. Other energy efficiency reduces operational costs and environmental footprints.

Top Future Trends in Defense Manufacturing:

Here are some of the future trends that can help in shaping the future of defense manufacturing:- Automation: AI is changing everything, and the lack of skilled labour is working as a catalyst for more widespread adoption of automation. Automated material handling features are reducing the need for manual labour, while robotic integration brings more flexibility and precision to the manufacturing. Advanced robotic systems can perform operations that were previously impossible with traditional machining methods.

- Smart manufacturing: IoT sensor integration is also seeing a steep rise, which provides real time monitoring of equipment health and production performance. The cloud based manufacturing systems allow for remote monitoring and control of CNC based operations.

- Additive manufacturing integration: Hybrid manufacturing systems are being used for manufacturing defense equipment. This helps in doing complex internal manufacturing which is complex for conventional manufacturing methods alone.

Top machine models used for manufacturing defense parts:

Here are some of the top defense products that are machined using CNC machines, and here are the machines you might select for machining a particular part:

- Weapon mounting brackets: Haas VF-2SS

- Satellite communication modules: DMG MORI DMU 50

- Surveillance camera housings: Mazak Integrex i-200

- Military-grade fasteners: Tsugami S206 Swiss-type Lathe

- Turbine engine components: DMG Mori DMU 340 P

- Gun barrels and receivers: Haas ST-30Y

- Radar system housings: Okuma MU-6300V

- Aircraft structural components: Mazak Variaxis i-800

- Heat-resistant alloys for jet propulsion: Makino T1

- Ballistic-resistant shielding: Haas EC-1600 Horizontal Mill

- Aerospace bearings for fighter jets: Okuma MULTUS U3000

- Cybersecurity hardware components: FANUC Robodrill α-D21MiB Plus

- Tank armor plating: Pama Speedmat HP

- Submarine propulsion parts: DMG Mori NTX 3000

- Defense electronics casings: Haas VF-2SS

- Defense robotics parts: DMG MORI NTX 2000

- Armored vehicle door hinges: Doosan Puma 3100 Lathe

- Spacecraft brackets and fixtures: Makino a61nx

- UAV (Unmanned Aerial Vehicle) frames: Hermle C 42 U

Conclusion:

Defense manufacturing is a very tough business, due to the extremely high demands and tight regulations. The machining of defense products needs high quality CNC machines and top notch operators. But having both of these together can cause a budget problem for small businesses, so they can look for affordable machines in MachineStation.

New Arrivals