*All specifications are approximations and are subject to verification. Comes as shown in the images. Please give us a call if you have any questions before purchasing. All sales are final.*

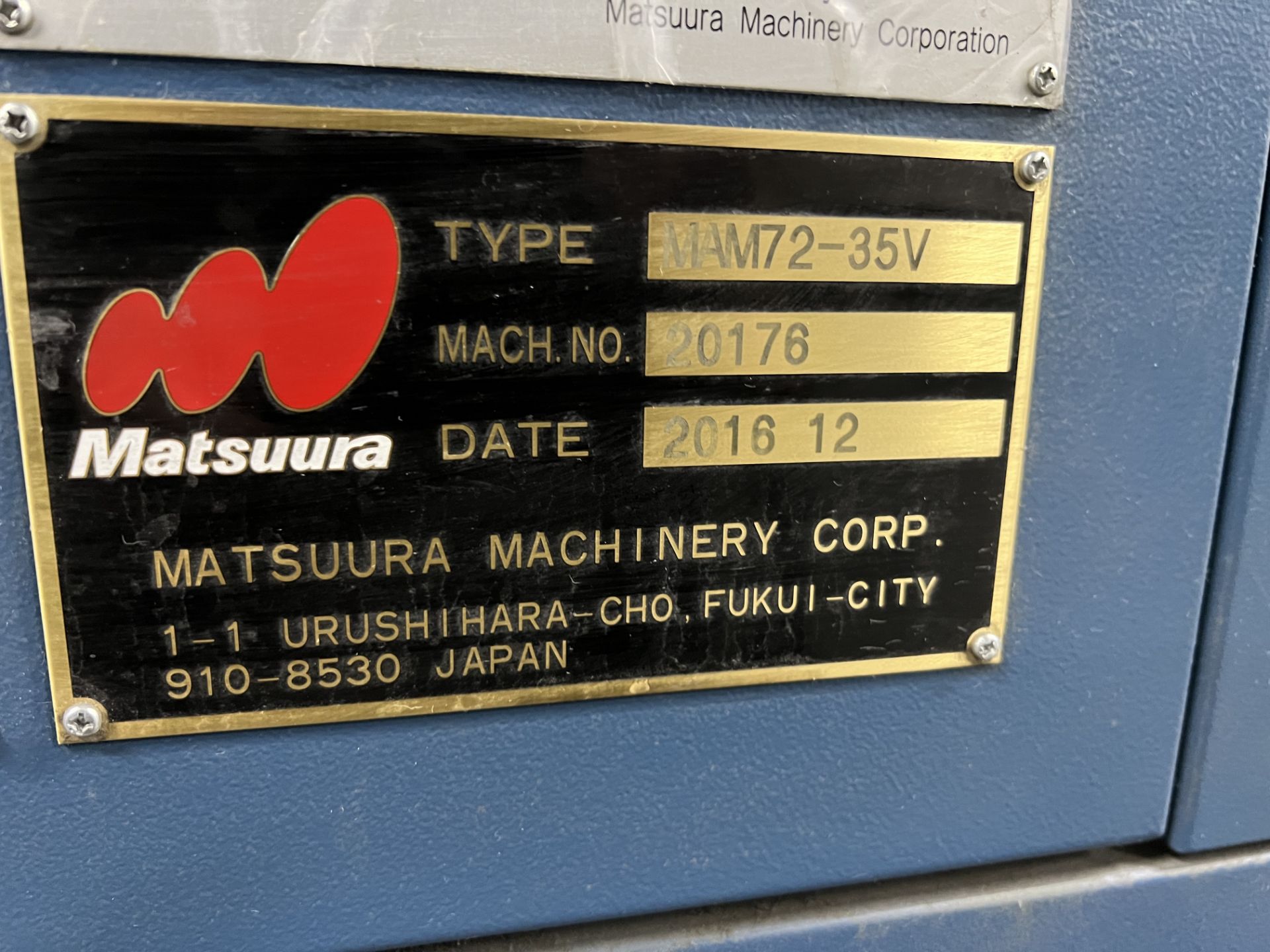

| Make: | Matsuura |

| Model: | MAM 72-35V |

| Year: | 2016 |

| Condition: | Used – Good |

| Machine Type: | 5-Axis Vertical Machining Center |

| Country of Origin: | Japan |

| Equipped With: |

|---|

- Full 5-Axis Simultaneous Machining (X, Y, Z, A, B)

- Trunnion-Style Rotary Table (Tilting & Rotary Axes)

- High-Speed Spindle

- Automatic Tool Changer (ATC)

- Fanuc CNC Control (Typically 30i Series)

- Rigid Tapping

- High-Speed Look-Ahead & Contour Control

- Through-Spindle Coolant (Option Dependent)

- Coolant System & Chip Management

- Fully Enclosed Guarding

- Automatic Lubrication System

|

| Axis Travels: |

|---|

- X-Axis Travel: Approx. 27.6″ (700 mm)

- Y-Axis Travel: Approx. 23.6″ (600 mm)

- Z-Axis Travel: Approx. 23.6″ (600 mm)

- A-Axis (Tilt): Approx. ±120°

- B-Axis (Rotation): 360° Continuous

|

| Table / Workholding: |

|---|

- Table Diameter: Approx. 13.8″ (350 mm)

- Maximum Workpiece Diameter: Approx. 28″ (700 mm)

- Maximum Workpiece Height: Approx. 19.7″ (500 mm)

- Maximum Table Load: Approx. 770 lbs (350 kg)

- High-Accuracy Direct-Drive Rotary Axes

|

| Spindle: |

|---|

- Spindle Taper: HSK-A63

- Maximum Spindle Speed: 12,000 RPM (20,000 RPM Optional)

- Spindle Motor Power: Approx. 22 HP (Continuous)

- High Torque, High Rigidity Design

- Oil-Air / Chiller-Assisted Spindle Cooling

|

| Automatic Tool Changer: |

|---|

- Tool Capacity: 60 Tools (Standard)

- Maximum Tool Diameter: Approx. 3.1″ (80 mm)

- Maximum Tool Length: Approx. 15.7″ (400 mm)

- Maximum Tool Weight: Approx. 17.6 lbs (8 kg)

- High-Speed Tool-to-Tool Change

|

| Feedrates: |

|---|

- Rapid Traverse (X / Y / Z): Approx. 1,575 IPM (40 m/min)

- Maximum Cutting Feedrate: Approx. 1,181 IPM (30 m/min)

- High-Precision Linear Guideways

|

| Accuracy: |

|---|

- Positioning Accuracy: ±0.0002″ (±0.005 mm)

- Repeatability: ±0.00008″ (±0.002 mm)

- Designed for Aerospace & High-Precision Components

|

| Electrical: |

|---|

- Power Requirement: 200 – 220 V / 3-Phase

- Frequency: 50 / 60 Hz

- Control Voltage: 24 VDC

|

| General: |

|---|

- Approx. Machine Weight: 22,000 – 24,000 lbs

- Construction: Heavy-Duty Meehanite Cast Iron

- Excellent Thermal Stability

- Compact Footprint for 5-Axis Machining

|

| Typical Applications: |

|---|

- Aerospace Components

- Medical Implants

- Complex 5-Axis Milling

- Precision Aluminum & Titanium Parts

- High-Mix / Low-Volume Production

|

| Key Advantages: |

|---|

- Proven Matsuura 5-Axis Accuracy & Reliability

- Excellent Surface Finish & Tight Tolerances

- Compact, Rigid, and Production-Ready Design

- Ideal for Simultaneous 5-Axis Machining

|