*All specifications are approximations and are subject to verification. Comes as shown in the images. Please call us if you have any questions before making a purchase. All sales are final.*

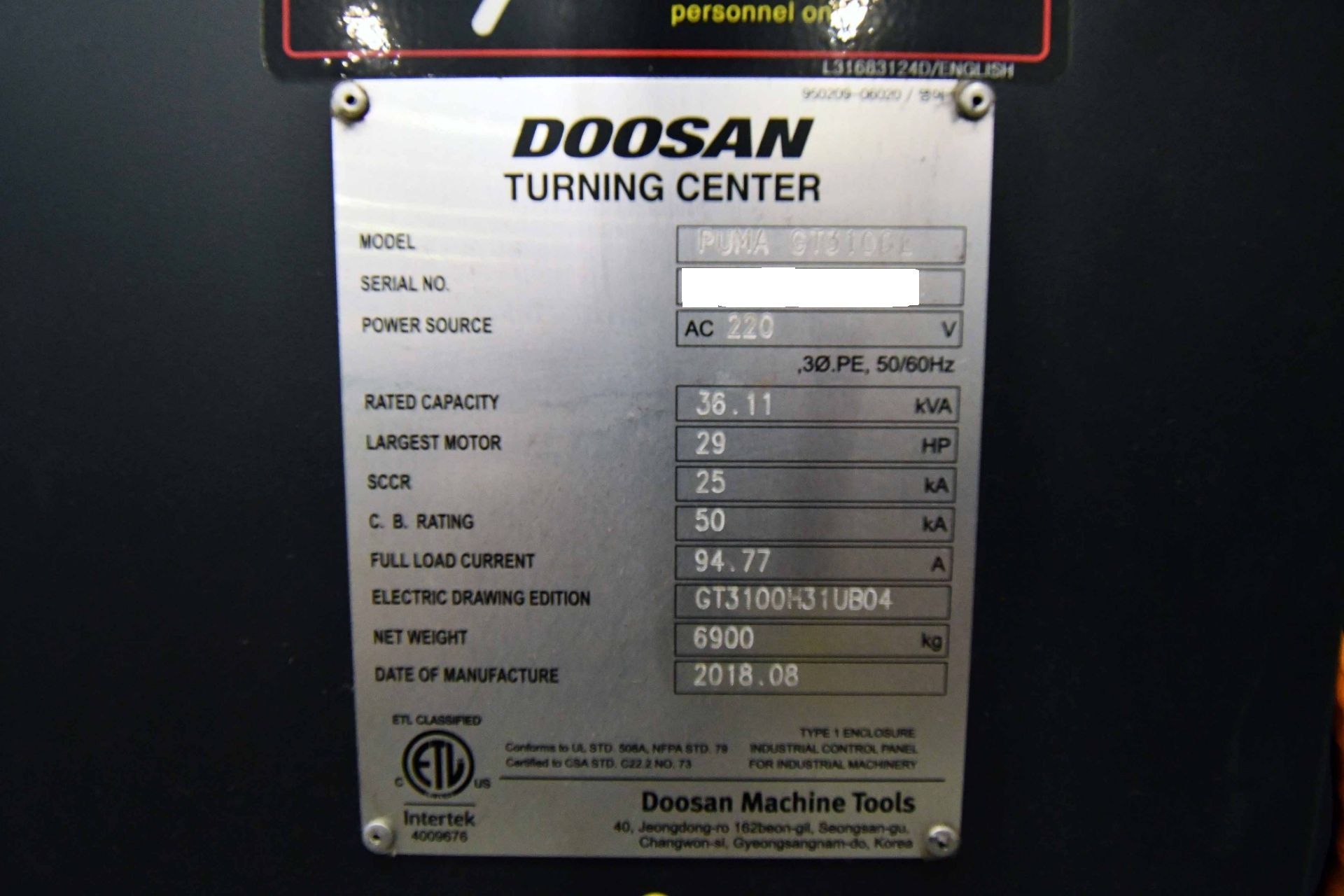

| Make: | Doosan |

| Model: | PUMA GT3100L |

| Machine Type: | CNC Turning Center – Long Bed |

| Condition: | Used |

| General: |

|---|

| Series: PUMA GT |

| Configuration: Long-Bed (L) |

| Axes: 2-Axis (X, Z) |

| Guideway Type: Box Guideways on All Axes |

| CNC Control: Doosan Fanuc i |

| Capacity: |

|---|

| Standard Chuck Size: 12″ |

| Optional Chuck Size: 15″ |

| Max Turning Diameter: 18.9″ |

| Max Turning Length: 50.2″ |

| Bar Capacity: 4.0″ |

| Travels & Rapid Traverse: |

|---|

| X-Axis Travel: 10.2″ |

| Z-Axis Travel: 53.1″ |

| Rapid Traverse X-Axis: 945 IPM |

| Rapid Traverse Z-Axis: 1,181 IPM |

| Spindle: |

|---|

| Max Spindle Speed: 2,800 RPM |

| Spindle Motor Power: 35 HP (S3 25%) / 30 HP (30 Min) / 22 HP (Continuous) |

| Max Spindle Torque: 1,190 lb-ft |

| Spindle Type: Gear-Driven High-Torque Spindle |

| Turret: |

|---|

| Turret Type: Servo Indexing Turret |

| Tool Stations: 10 or 12 Stations |

| Indexing: Servo Motor Controlled |

| Tailstock: |

|---|

| Tailstock Type: Programmable Hydraulic |

| Tailstock Travel: 53.1″ |

| Quill Diameter: 3.9″ |

| Quill Travel: 3.9″ |

| Coolant System: |

|---|

| Coolant Tank Capacity: 72.7 gal |

| Standard Coolant Pressure: 22 PSI |

| Optional High-Pressure Coolant: Up to 1,015 PSI |

| Filtration Options: Screen, Dual Bag, or Paper Filter |

| Chip Management: |

|---|

| Chip Conveyor Options: Hinged Belt, Screw Type, Magnetic Scraper |

| Chip Discharge: Side or Rear (Configuration Dependent) |

| CNC Control & Operation: |

|---|

| Display: 10.4″ Color LCD |

| Input: QWERTY Keyboard |

| Connectivity: USB & PCMCIA |

| Software Features: Tool Load Monitoring, Turret Recovery Assistance, Work & Cycle Time Management |

| Dimensions: |

|---|

| Overall Length: 182.5″ |

| Overall Width: 80.1″ |

| Overall Height: 83.1″ |

| Length with Chip Conveyor: 227.4″ |

| Standard & Optional Equipment: |

|---|

| Dual Pressure Chucking |

| Chuck Clamp Confirmation |

| Hydraulic Steady Rest (Optional) |

| Tool Setter (Manual or Automatic) |

| Auto Door |

| Bar Feeder Interface |

| Linear Scales (X/Z – Optional) |

| Mist Collector |

| Part Catcher |