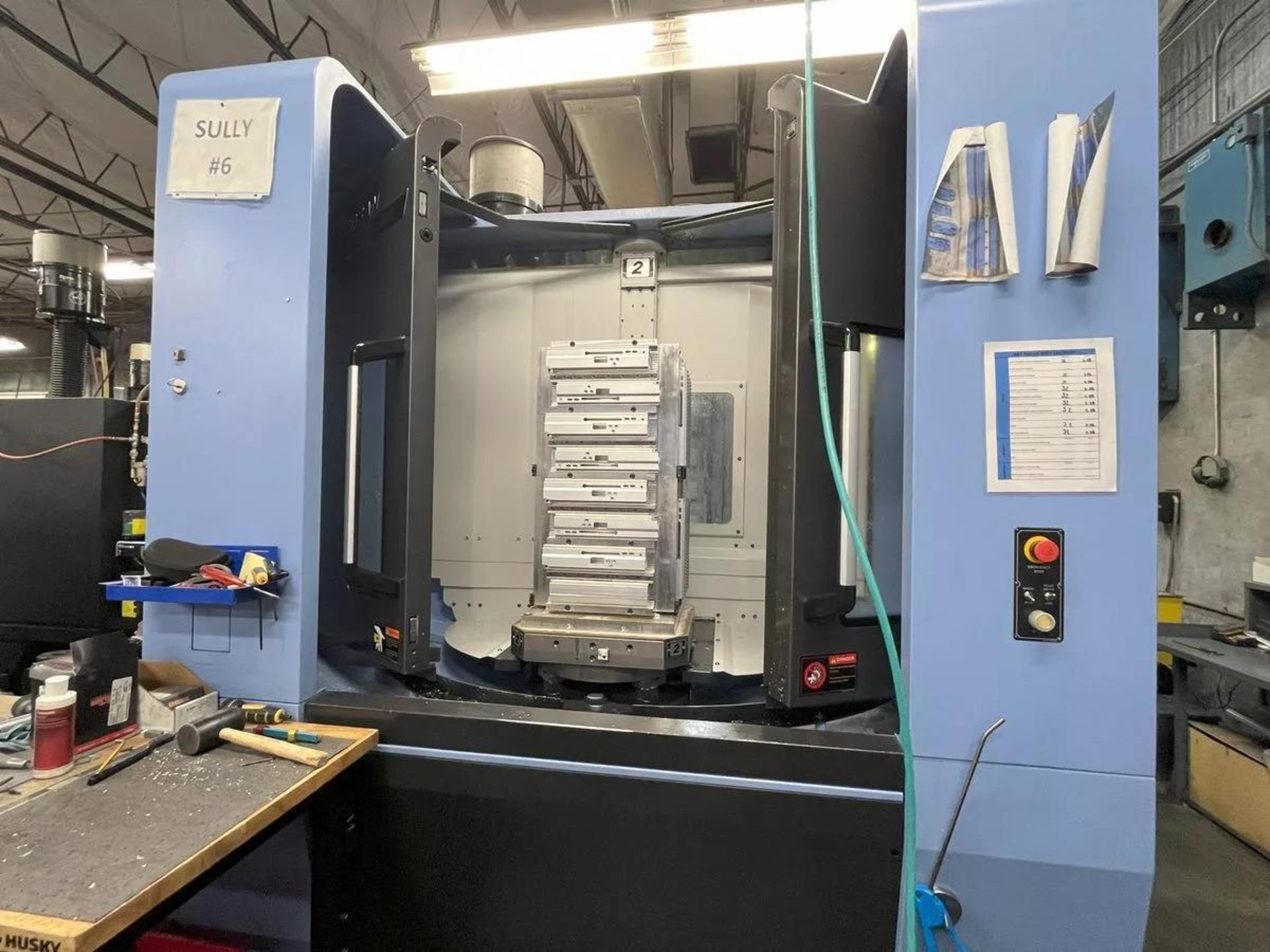

*All specifications are approximations and are subject to verification. Comes as shown in the images. Please call us if you have any questions before making a purchase. All sales are final.*

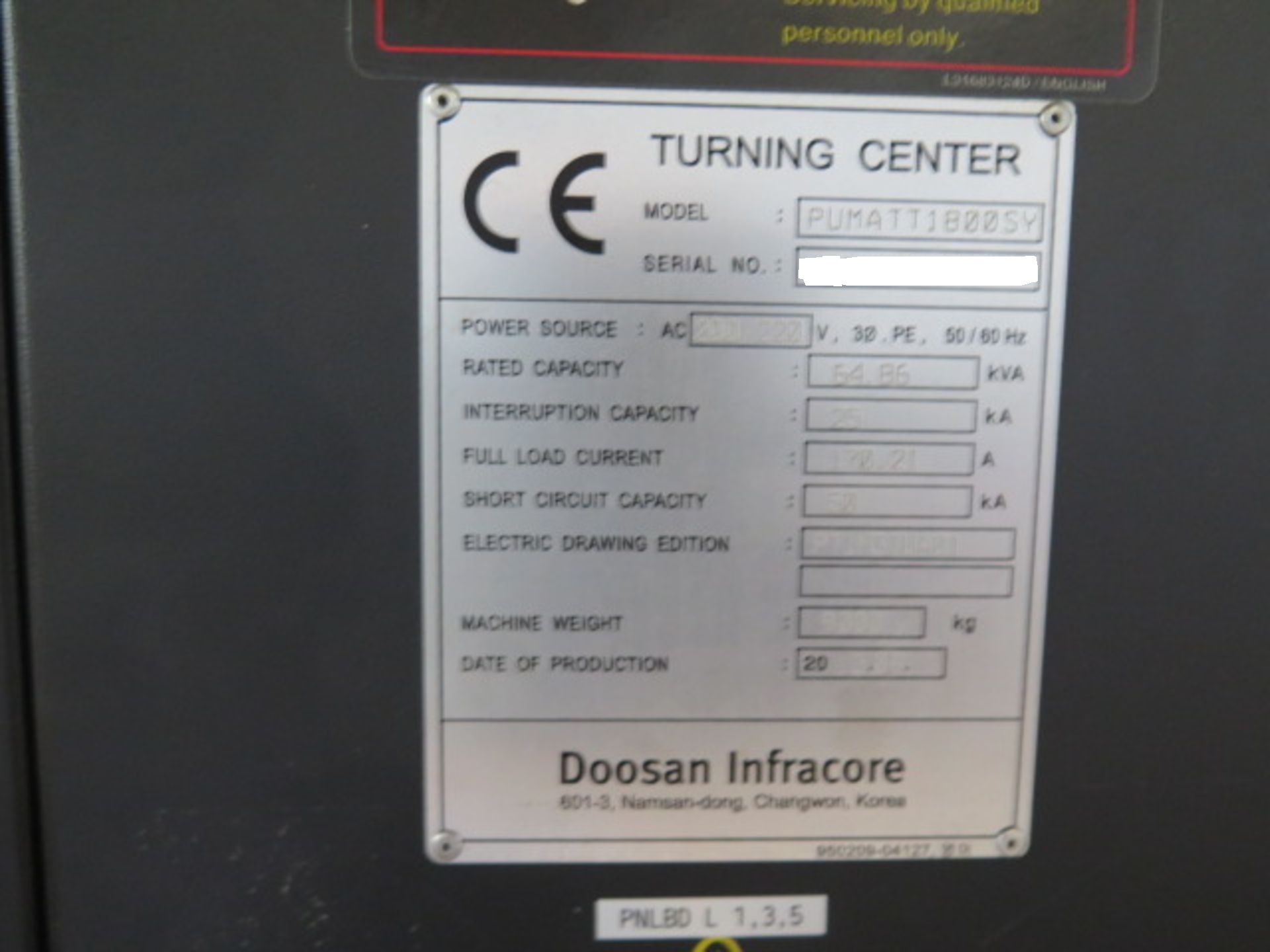

| Make: | Doosan |

| Model: | PUMA TT1800SY |

| Year: | 2013 |

| Machine Type: | Twin-Spindle, Twin-Turret CNC Turning Center with Y-Axis |

| Country of Origin: | Korea |

| Condition: | Used – Good |

| Equipped With: |

|---|

- Doosan FANUC i Plus CNC Control (FANUC 31i Series)

- Twin Opposed Spindles

- Upper & Lower BMT Turrets

- Y-Axis Milling Capability

- C-Axis on Left & Right Spindles

- Live Tooling

- Automatic Part Transfer

- Parts Catcher & Unloader

- Bar Feeder Interface

|

| Turning Capacity: |

|---|

- Swing Over Bed: 9.1″

- Swing Over Saddle: 9.1″

- Recommended Turning Diameter: 8.3″

- Max Turning Diameter (Upper / Lower): 9.1″

- Max Turning Length: 9.1″

- Bar Capacity: 2.6″

|

| Axis Configuration & Travels: |

|---|

- Total Controlled Axes: 8

- X1 Travel: 6.5″

- X2 Travel: 7.5″

- Z1 Travel: 27.6″

- Z2 Travel: 28.3″

- Y-Axis Travel: ±1.97″

- A-Axis (Spindle Distance): 30.3″

|

| Rapid Traverse Rates: |

|---|

- X1 / X2: 787 IPM

- Z1 / Z2: 1,575 IPM

- Y-Axis: 295 IPM

- A-Axis: 1,575 IPM

|

| Main & Sub Spindles (Identical): |

|---|

- Spindle Type: Built-In Motor Spindle

- Chuck Size: 8″ Hydraulic

- Spindle Speed: 5,000 RPM

- Spindle Nose: A2-6

- Spindle Bore: 3.0″

- C-Axis Resolution: 0.001°

- Spindle Power: 25 HP (30-min) / 24.8 HP (Continuous)

- Max Spindle Torque: 153.5 ft-lbs

|

| Turrets: |

|---|

- Upper & Lower BMT 55P Turrets

- 12 Stations per Turret

- 24 Index Positions per Turret

- Total Tool Positions: Up to 48

- Index Time: 0.15 sec

- Max OD Tool Size: 0.79″ × 0.79″

- Max ID Tool Size: 1.3″

|

| Live Tooling / Milling: |

|---|

- Max Live Tool Speed: 5,000 RPM

- Live Tool Power: 7.4 HP (S3 25%) / 1.5 HP (Continuous)

- Live Tool Torque: 34.7 ft-lbs

|

| Control & Software: |

|---|

- Doosan FANUC i Plus CNC Control

- 15″ Color LCD

- EZ-Guide i Conversational Programming

- Dual-Path Machining

- USB / Ethernet / RS-232 Interfaces

- Collision Avoidance & Tool Monitoring

|

| Coolant & Chip Management: |

|---|

- Standard Coolant Pressure: 65 PSI

- Optional High-Pressure Coolant up to 1,015 PSI

- Through-Spindle Coolant (Left & Right)

- Optional Chip Conveyor

- Optional Mist Collector

|

| Electrical: |

|---|

- Power Requirement: 75.21 kVA

- Voltage: 200 / 220V, 3-Phase, 50 / 60 Hz

|

| General: |

|---|

- Overall Dimensions (Approx.): 158.2″ L × 85.1″ W × 82.1″ H

- Machine Weight (Approx.): 19,400 lbs

|