*All specifications are approximations and are subject to verification. Comes as shown in the images. Please give us a call if you have any questions before purchasing. All sales are final.*

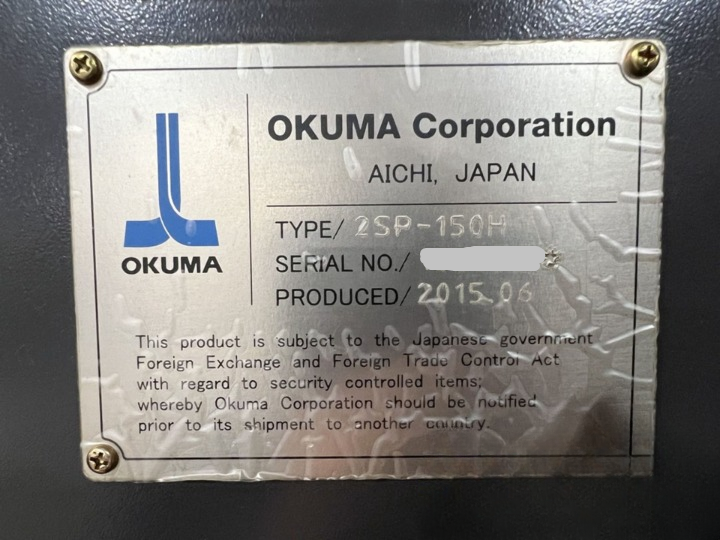

| Make: | Okuma |

| Model: | 2SP-150H |

| Year: | 2015 |

| Condition: | Used – Good |

| Machine Type: | Twin-Spindle CNC Turning Center |

| Country of Origin: | Japan |

| Machine Configuration: |

|---|

- Dual Spindle CNC Turning Center

- Main Spindle + Sub Spindle (Opposed Spindle Design)

- Simultaneous Front & Back Machining

- Single Turret, High-Rigidity Layout

- Designed for High-Volume Production

|

| CNC Control: |

|---|

- Okuma OSP-P300 CNC Control (OSP-P200 on Some Builds)

- Okuma Proprietary CNC Platform

- 15″ Color LCD Display

- Conversational & G-Code Programming

- High-Speed Program Processing

- Thermo-Friendly Concept

- Collision Avoidance System (CAS – Optional)

- Ethernet & USB Connectivity

- Tool Life Management

- Graphic Simulation & Alarm Diagnostics

|

| Axis Travels: |

|---|

- X-Axis Travel: Approx. 6.3″ (160 mm)

- Z-Axis Travel: Approx. 15.7″ (400 mm)

- C-Axis: Full C-Axis on Main & Sub Spindle

|

| Spindle Specifications: |

|---|

- Main Spindle

- Chuck Size: 6″

- Spindle Nose: A2-5

- Maximum Spindle Speed: Approx. 6,000 RPM

- Spindle Motor Power: Approx. 15 HP

- C-Axis Indexing

- Sub Spindle

- Chuck Size: 6″

- Spindle Nose: A2-5

- Maximum Spindle Speed: Approx. 6,000 RPM

- Spindle Synchronization (Main ↔ Sub)

|

| Turret & Tooling: |

|---|

- Turret Type: Servo-Driven Turret

- Number of Stations: 12

- Tool Size: Turning Tools

- Live Tooling: Optional (Configuration Dependent)

- Rapid Tool Indexing

- Rigid Tool Clamping

|

| Turning Capacity: |

|---|

- Maximum Turning Diameter: Approx. 9.8″ (250 mm)

- Maximum Turning Length: Approx. 13.8″ (350 mm)

- Bar Capacity: Approx. 1.6″ (40 mm)

|

| Feedrates & Rapids: |

|---|

- Rapid Traverse (X / Z): Approx. 945 IPM (24 m/min)

- High-Precision AC Servo Drives

|

| Coolant & Chip Management: |

|---|

- Flood Coolant System

- Programmable Coolant Nozzles

- Chip Conveyor (Standard / Optional)

- Automatic Chip Disposal Design

|

| Electrical Specifications: |

|---|

- Power Supply: 220 / 400 / 480 V

- Phase: 3-Phase

- Frequency: 50 / 60 Hz

- Control Voltage: AC / DC via Okuma CNC

- Industrial-Grade Electrical Cabinet

|

| Safety & Reliability: |

|---|

- Full Machine Enclosure

- Interlocked Safety Doors

- Emergency Stop System

- Overload & Servo Monitoring

- Automatic Central Lubrication System

- Okuma Thermo-Friendly Structure for Accuracy

|

| Key Features & Advantages: |

|---|

- True Twin-Spindle Productivity

- Complete Front & Back Machining in One Cycle

- Reduced Cycle Time & Part Handling

- Excellent Accuracy & Thermal Stability

- Ideal for Automotive, Medical & Precision Parts

- Proven Okuma Reliability & Long Service Life

|

| Typical Applications: |

|---|

- High-Volume Production Turning

- Automotive Components

- Hydraulic & Pneumatic Parts

- Precision Shafts & Bushings

- Medical & Industrial Fittings

|