AeroSpace

Table of Contents

- All about aerospace CNC machining: Things you must know

- What is Aerospace CNC Machining?

- Why Does Aerospace CNC Machining Matter? (The Benefits of it):

- What Materials are Machined Using CNC Machines in the Aerospace Sector?

- What types of CNC Machines are used in Aerospace precision machining?

- Which Aerospace Products are Made Using CNC Machines?

- Tips for Machining Aerospace Parts with CNC Machines:

- Future Trends in the World of Aerospace CNC Machining

- Top Aerospace Parts and their required CNC Models

- Conclusion

Quick Contact

All About Aerospace CNC machining: Things you must know

According to a report, the Aerospace manufacturing market size is estimated to be $ 913.13 billion in 2023, and the market is expected to reach $ 1.24 trillion approximately by 2030.

What is Aerospace CNC Machining?

Aerospace CNC machining is about the usage of different types of CNC machines for the manufacturing of Aerospace products like turbine blades, engines, wing spurs, wing ribs, exhaust components, cabin interior fittings, and many more things.

Unlike traditional manual machining, CNC machining automates the cutting process and helps in high precision machining while achieving extremely tight tolerances, which is important for safety protocols of the aerospace sector. Also, the majority of the aerospace CNC machining parts have very complex geometries, which can be easily manufactured with the help of multi axis CNC machines in just one setup.

Why Does Aerospace CNC Machining Matter? (The Benefits of it):

Here are some of the benefits of CNC machining for aerospace industry:

- Minimal flaws in products: A majority of the aerospace parts that get manufactured have critical importance regarding the overall performance of the aeroplane or the rocket. One small mistake in the products can cause catastrophic damage. Parts made using traditional machining are prone to dimensional error due to human intervention. This is not applicable for multi axis high end CNC machines. The quality bar is codified in AS9100 (the aerospace quality management standard based on ISO 9001, with added requirements for risk, configuration, counterfeit prevention, and traceability).

- Thin walled geometries: The aerospace CNC machining companies need several thin walled lightweight parts, which are not easy to manufacture. These thin wall dimensions are not easy to achieve. But it can be achieved with the help of high performing CNC machines. CNC precision machining can create thin wall materials from robust yet lightweight raw workpieces in a hassle-free manner.

- High precision: The aerospace manufacturing industry demands the highest standard of accuracy and precision. All the parts must meet strict tolerances and adhere to rigorous quality standards. It is very important to maintain that accuracy and precision for the sake of safety at first. The modern high end CNC machines can provide that level of unparalleled precision and accuracy.

- Efficiency: The aerospace parts are costly, and one small mistake can make the whole product invalid for use. So, it is very important for aerospace CNC machining shops to maintain a high level of efficiency. The CNC machines are known for reducing human intervention, decreasing manual errors. The modern machines are even more automated, making the whole manufacturing process much more seamless and efficient.

- Complexity and flexibility: Most of the parts of the aerospace industry have a very complex geometry, and they’re almost impossible to manufacture using manual machining. CNC machines can manufacture highly complex parts with ease. A multi axis CNC machine can work on a material from multiple sides at a time, making it easier to make complex geometries. Also, the combination of CAD and CAM software in CNC machines helps the manufacturers to design, refine, and finally create a piece seamlessly.

- Innovation: Last but not least, innovation is very important for such high tech industries. All the aerospace machining companies are heavily focused on R&D to develop the best aeroplane, rocket, or fighter aircraft. CNC machines play an important role in that work. The multi-function CNC machines help people in prototyping new products, and get even the most complex of designings done in an easy way.

What Materials are Machined Using CNC Machines in the Aerospace Sector?

Here is the list of the main materials that are machined using a CNC machine in the Aerospace sector:

- Aluminum alloys: It is one of the most widely used materials for manufacturing aerospace products. The main reason behind the usage of aluminium alloys for aerospace manufacturing is their lightweight and high strength-to-weight ratio, and corrosion resistance.

The most commonly used aluminium alloy grade in the aerospace industry is 7075-T6, and its primary alloying component is zinc. This material is mostly used for manufacturing fuselage, structural components, and several wings because it offers good fatigue strength.The machining challenges with aluminium alloys are burr formation, thin walls, and thermal expansion.

- Titanium alloys: The Aerospace sector is the industry that needs the highest amount of titanium alloys globally. They provide exceptional strength-to-weight ratios and corrosion resistance. The metal is also well celebrated for its capability of functioning well, even at high temperatures.

Both commercial and military aircraft employ a significant amount of these materials for building their different parts. Different parts of aeroplanes and fighter jets, like components of jet engines, discs, blades, casings, and shafts, are made using this material.Some of the challenges faced while machining titanium alloys are work hardening, spring back, and low thermal conductivity. - Engineering plastics: They are known for their vibration resistance and incredibly low weight. They have excellent sealing capabilities and chemical resistance, too. These materials are well known for their top tier impact and are considered a great alternative to metals.

Ultem, polycarbonate, and PEEK are some of the top performing polymers that are regularly used for machining aerospace components. They can be used to create aircraft parts like tray tables, wear pads, armrests, cabin interiors, valve components, insulation, tubing, and back-lit instrument panels.

- Composite materials: Different types of composite materials, like carbon fiber and glass fiber, are used for manufacturing different aerospace components. They are mainly used for their ultra lightweight features. These materials are also well celebrated for their high strength and fatigue resistance.

There are different challenges while machining these materials, like delamination, dust control, and tool wear. You can use specialized cutting tools for the sake of avoiding delamination.

What types of CNC Machines are used in Aerospace precision machining?

Here are some of the top aviation CNC machines that are used for machining different aerospace products:

- 5-axis CNC milling machines: These machines are considered the workhorses of modern aerospace milling works. These machines with three obvious axes and two rotational axes help in manufacturing parts with the most complex geometries.

The major benefits of these machines include fewer setup requirements, tight tolerances, and superior surface finish. They can be used to manufacture different parts like turbine blades, impellers, and structural parts.

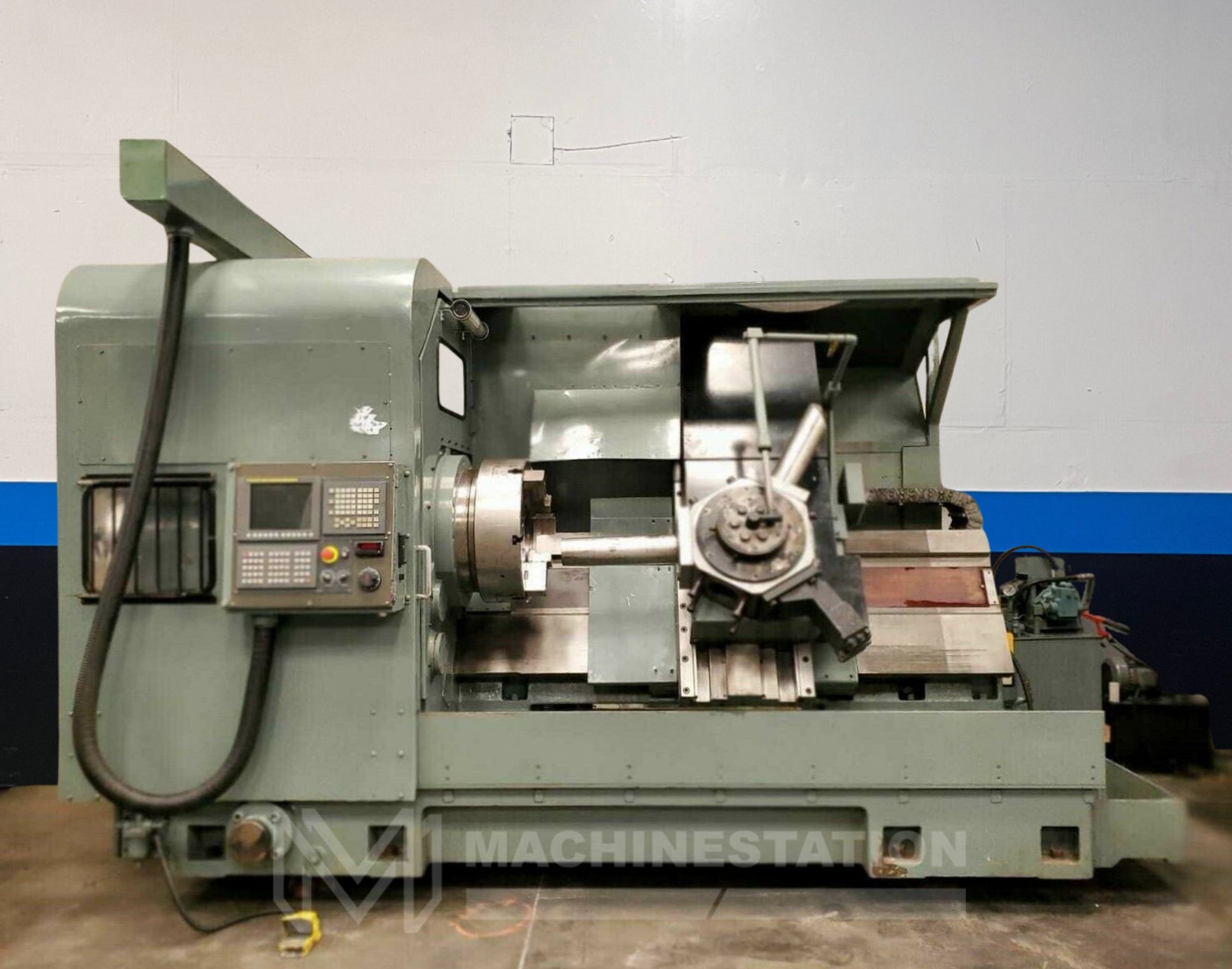

- CNC turning centers: These machines are used for making parts that are cylindrical or circular in shape. Different parts like the shaft, fasteners, and bearings of aircraft are made using these types of CNC machines.

These machines have high-dimensional accuracy. They are also pretty cost-efficient and bring high precision within an affordable budget range.

- CNC mill-turn machines: They are known as the multi-tasking machines or multi-function machines. They can be used for both aerospace milling and turning operations with a workpiece in just a single setup. Several complex components can easily be made with the help of these CNC machines.

Their main benefit is that they help in streamlining the production process. No human intervention needed. Reducing error risks. They help in making complex structures of the engine and hydraulic system.

- CNC grinding machines: These CNC machines are used for giving fine surface finishing to the machine products for the aerospace industry. They help achieve the finest level of tolerances needed for the critical parts.

- CNC laser cutters: CNC laser cutters use laser beams for cutting the workpieces into the shape of the demanded material. You can also do engraving and marking using these machines.

These CNC machines are well known for their high precision machining capabilities and the clean edges that it can provide. These machines are excellent when it comes to cutting thin metals and composites.

- CNC waterjet cutters: These machines use high pressure water with an abrasive to cut the raw workpieces. These machines are well celebrated for their capability of being able to cut thick and hard materials without generating heat and causing thermal deformation. They help in preserving the material’s integrity.

Which Aerospace Products are Made Using CNC Machines?

Here are some of the aerospace products that can be made using CNC machines:

- Engine components: The most critical and important sector in aerospace precision machining is the engine components manufacturing sector. Different engine components like turbine blades, fan discs, compressor discs, engine casings, fuel nozzles, impellers, and compressor housings are made with the help of CNC machines.

Different types of machining are needed to manufacture these parts, like precision turning, 5-axis milling, and grinding. These parts are made up of high strength alloys or stainless steel so that they can withstand extreme temperatures and stresses. Also, these parts need to maintain extremely tight tolerances, so high end machines are needed for better machining.

- Structural components: CNC machines are used to machine parts that form the skeleton of the aircraft or the rockets. Different structural parts like wing ribs, fuselage frames, stringers, spars, bulkheads, and other lightweight airframe parts are made using these CNC machines.

Different aerospace precision machining processes like 5-axis milling, laser cutting, and waterjet cutting are used to manufacture these parts. They are often made using lightweight aluminium alloys, which further helps in enhancing the fuel efficiency while keeping the structural integrity intact.

- Landing gear instruments: Landing gears are prime examples of top notch machining capabilities. Many of these landing gear instruments, like struts, braces, actuators, and links, are made with the help of CNC machines.

Turning, milling, and grinding machines are used to get these manufacturing jobs done. These products are made with different robust materials like steel and titanium. These materials need durability and precision so that they can handle the immense load during takeoff and landing.

- Avionics and electrical components: Different electronic components of a CNC machine are made with the help of the CNC machine. Parts like control panels, connectors, sensor housing, and avionics enclosures are all made with the help of CNC machines. These parts need proper precision machining to ensure top notch quality and connectivity.

CNC milling machines of high precision. CNC laser cutting machines are needed to manufacture most of these parts. These parts are made up of aluminium and other high performance plastics, which ensure proper electrical connectivity and electromagnetic shielding.

- Interior components: Different types of internal components of an aircraft are made up with the help of CNC machines, like seat frames, tray tables, overhead bins, cabin panels, brackets, mounting clamps, and other decorative elements. These parts need to be machined and assembled in the right way for the sake of passenger safety and comfort, and system reliability.

CNC machines help in making the intricate designs needed to make these parts, and also help with precise cutouts and fine details, which help in further enhancing the aesthetics and functionality of the aircraft. CNC milling machines, CNC laser cutters, and CNC routers are needed for making these parts. These parts are mainly made with elements like composites, aluminium, and other plastics.

- Prototyping: Prototyping helps scientists and engineers to develop new parts that can make the whole aerospace industry more efficient and advanced. Through prototyping, they can make new designs, evaluate them to check the fit and functionality before using them for mainstream work.

Different kinds of machines, like milling machines, lathes, hybrid machines, laser cutters, and grinders, are needed for making new parts and giving them fine finishing for testing.

Tips for Machining Aerospace Parts with CNC Machines:

Here are some of the major tips that you need to follow while machining aerospace parts with CNC machines:- Optimize material selection: First step is, verify which materials you are going to use and buy a machine as per your material needs. Some extra hard materials that have a very high strength-to-weight ratio can only be machined using some selective machines. So make sure to optimize the materials as per your machine collection or vice versa.

- Follow process optimization strategies: Start by breaking the whole process into different small parts, based on the operations and characteristics of the material. This process helps in optimal tool selection for the right task. Also, implement proper workholding and fixturing to ensure consistent part location and vibration control.

- Precision and tolerance control: Precision and tight tolerances are both very important for aerospace CNC machining. Ensure you can achieve that tolerance level by generating the right G-code, and also, if needed, use machines like 5-axis or 9-axis CNC machines for better precision of complex geometries.

- Use advanced tooling: Advanced tooling options are needed for different tough materials. Use carbide-coated tools for machining strong materials. Implement coolant through cooling to enhance the tool life and ensure better performance.

- Surface finishing: Proper surface finishing is very important for aerospace products. Different methods, like anodizing, polishing, passivation, and powder coating for better durability and aesthetics.

Future Trends in the World of Aerospace CNC Machining:

Here are some of the major trends that are shaping or will shape the future of aerospace CNC machining:- Integration of additive manufacturing: 3D printing is getting more and more famous with the passing time. So combination of additive machining with CNC machining has helped in better manufacturing of complex geometrical parts. This method also enables lightweight designs and faster prototyping.

- Automation and robotics: Automation helps in faster and seamless production of different products, that too, without any human intervention. The system also does real-time toolpath optimization, with AI driven toolpath and process adjustments. Robots can help with lights-out manufacturing, increasing overall productivity, and helping to increase revenue.

- Industry 4.0 and IOT integration: Modern manufacturing is also getting heavily dependent on IOT. IOT helps in real-time monitoring of the tool life and the product quality that is being machined. Digital twin technology also helps in virtual simulations of the machining process by optimizing the design before production.

- Sustainability and green manufacturing: Though tech advancement and manufacturing growth are important, nature is also important at the same time. So, more sustainable manufacturing methods are being introduced with a focus on reducing waste, energy consumption, and using more environmentally friendly materials. Recyclable coolants are also being used.

Top Aerospace Parts and their required CNC Models:

Here are some of the major aerospace parts that can be machined CNC machines, and the preferred CNC model that you might use:

- Turbine Blades: DMG MORI DMU 85 monoBLOCK

- Engine Casings: Mazak INTEGREX i-400

- Landing Gear Components: Okuma MULTUS U4000

- Aircraft Brackets: Haas VF-5/50

- Wing ribs: Zimmermann FZ100

- Aerospace bearings: DMG MORI NLX 2500

- Aerospace gear assemblies: Gleason Phoenix 280G

- Composite material fasteners: Haas ST-20Y

- Engine compressor discs: Makino T1

- Spacecraft structural brackets: Hermle C 52 U MT

- Navigation system housings: Mazak Variaxis i-800 NEO

- Cabin interior fittings: Haas VF-4SS

- Wing Spars: Makino T1

- Actuator Housings: GF Machining Solutions Mikron MILL X 600 U

- Hydraulic Manifolds: Doosan DNM 6700

- Avionics Enclosures: Hurco VMX42i

- Airfoil Components: Hermle C 42 U

- Engine Mounts: Mitsubishi MVR-Ex Series

- Fuel Nozzles: Chiron FZ 16 S

- Instrument panel beads – Haas VF-2SS

- Cockpit control levers – Mazak Variaxis i-600

- Exhaust components – Makino T1

- Satellite structural parts – Zimmermann FZ100

- Aerospace bushings – Citizen Cincom L32

- Flap track fairings – Hermle C 52 U

- Cabin pressure components – Okuma MU-8000V

- Aircraft engine turbine discs – Okuma LU7000EX

- Propulsion system brackets – Haas UMC-750

- Pump housings – Makino a61nx

- Rocket nozzle components – DMG MORI DMU 340 P

- Precision ball screws – JTEKT (Toyoda) GS200H Grinder

- Structural fuselage parts – DMG MORI DMU 340 Gantry

- Radar system housings – Hermle C 42 U

- Aerospace connectors – Star SR-38 Swiss-Type Lathe

- Landing gear struts – Okuma MU-10000H

- Flight control rods – Doosan Puma 700XL Lathe

- Valve bodies – Makino a61nx

- Engine exhaust nozzles – DMG MORI LASERTEC 65 3D hybrid

- Titanium fasteners – Star SR-20RIV Swiss-Type Lathe

- Control surface hinges – Haas UMC-750

- Heat exchanger parts – Makino a61nx

- Oxygen system components – DMG MORI CMX 1100 V

- Antenna mounts – Mazak Variaxis i-800 NEO

- Avionics panel supports – Hermle C 22 U

- Fuel injection system components – Star SR-20R IV Swiss-Type Lathe

- Cooling system parts – Mazak Variaxis i-800 NEO

- Aerospace pistons – Doosan Puma 5100 Lathe

- Actuation system parts – Makino D500 5-Axis

- High-temperature engine seals – Okuma LB3000 EX II

- UAV (Unmanned Aerial Vehicle) components – DMG MORI DMU 75 monoBLOCK

Conclusion:

Aerospace CNC machining is a tough and complex engineering task. You will have to follow tight tolerances, maintain high precision, and manufacture parts with complex geometries.

Several machines are employed for these jobs. Each has its own importance, depending on the material. Also, do a detailed research about which machine can be the best for your aerospace machining works, and then check for its used model on our site.

New Arrivals