Medical

Table of Contents

- All about Medical CNC Machining

- What is Medical CNC Machining?

- Why is CNC Machining Needed for Medical Products?

- Materials Used in Medical CNC Machining

- What are the Types of CNC Machines Used for Medical Machining?

- Medical Products Manufactured Using CNC Machines

- Future Trends in Medical CNC Machining

- Best Practices for Medical CNC Machining

- Top Medical Products and the Machine that might be Used for Machining it

- Conclusion

Quick Contact

All about Medical CNC Machining

According to a report, the global medical device contract manufacturing market size is estimated to be $ 76.8 billion in 2024, and the market is expected to reach $ 151.98 billion approximately by 2030, growing at a CAGR of 12.36%.

Medical Manufacturing is a very critical sector that needs precision manufacturing. The industry has demands for different small, intricate design parts that can only be manufactured using highly precise CNC machines. CNC machines serve as the backbone of medical manufacturing, as they can produce complex products from tough materials with ease, which is not possible with other traditional machining methods.

The medical industry needs micron level tolerances, especially for orthopedic implants and other surgery related materials, so medical CNC machining is done with the help of high end CNC machines of different configurations that can achieve that tolerance level.

So, if you’re someone who is in medical CNC machining services or wants to enter this industry, then this is the right page for you, as we will discuss the machines needed for medical manufacturing, materials used, products made, and all other things. Let’s get started!

What is Medical CNC Machining?

Medical CNC machining is the process of machining different medical products like orthopedical implants, dental crowns, and other surgical products with the help of different advanced CNC machines. These machining works cannot be done using traditional machining methods because they need high precision, regulatory compliance, and biocompatibility.

The CNC technology helps the manufacturers to achieve tolerance as tight as ±0.001 inches (±0.0254 mm). They also help in bringing repetability in manufacturing, which helps in producing identical products on a large scale, and that helps the large scale medical CNC machining services shops.

Why is CNC Machining Needed for Medical Products?

Here are some of the top reasons why CNC machines are most important for the manufacturing of medical products:

- Unparalleled precision: One of the biggest advantages that the CNC machines bring to the table when it comes to manufacturing is unparalleled precision and tight tolerances. They need tolerances measured in micrometers. CNC machines can repeatedly achieve these tolerances, which is important for implants and instruments.

- Biocompatible material compatibility: CNC machines can work with different kinds of materials, including biocompatible materials. They can process a wide range of FDA approved materials. Not only the hard to machine titanium alloys or stainless steel, CNC machines can also help in machining specialized plastics like PEEK. This versatility helps the manufacturers to machine different kinds of materials using the CNC machines.

- Complex geometric capabilities: The modern advanced 5-axis CNC machines can create complex design products like intricate surgical tools, custom fit implants, and other products with multi dimensional shapes. Multi axis CNC machines, like 5-axis or 7-axis, can produce these complex design parts in just one setup while reducing time and error.

- Regulatory compliance support: Medical products and devices need to follow a lot of regulatory compliance, or they become useless, and that level of perfection in manufacturing is hard to achieve with traditional machining methods. CNC machines become vital in these scenarios.

- Rapid prototyping: R&D is very important in the medical industry, and there is also a high demand for custom implants for different patients, which can be easily done with the help of CNC machines. The CNC machines can easily make the most complex of designs with ease, while traditional machining methods might not be able to do it.

Materials Used in Medical CNC Machining:

Here are some of the major materials that are used for manufacturing different kinds of medical products:

- Metals: Here are some types of materials that are used for making different kinds of medical products:

- Titanium and titanium alloys: Titanium is one of the most commonly machined materials by CNC machines. Grade 5 (Ti-6Al-4V) and Grade 23 (Ti-6Al-4V ELI) are commonly used for manufacturing medical products using CNC machines. Hip, knee replacements, bone plates, and spinal implants are made using these materials.

- Stainless steel: Stainless Steel is another well known metal for medical product machining. They have excellent corrosion resistance, durability, and ease of sterilization. They are also a very cost-effective material. The 304 stainless steel is used for manufacturing external medical components, while the 316L is used for surgical instruments and implants.

- Cobalt-chrome alloys: These are very hard metals, which also have superior wear resistance and excellent strength. They are very important for joint replacements, dental prosthetic applications, and other high-stress implants where durability is very important.

- Nitinol: This is a unique shape memory alloy that is super elastic. They are used for making superelastic instruments and guidewire tips. It is used for stents, orthodontic wires, and surgical tools for minimally invasive procedures.

- Advanced polymers and composites: Here are some of the main types of advanced polymers and composites that can be used in medical manufacturing:

- PEEK: PEEK has emerged as one of the revolutionary materials for medical product manufacturing. These materials not only provide biocompatibility but also radiolucency for imaging compatibility and chemical resistance. It is used as a lightweight alternative to metals for spinal implants, surgical instruments, and dental components.

- UHMWPE: This is Ultra-High Molecular Weight Polyethylene, and it is known for its low friction and top-notch wear resistance. These materials are widely used for artificial hip and knee joints, and other products for wear surfaces.

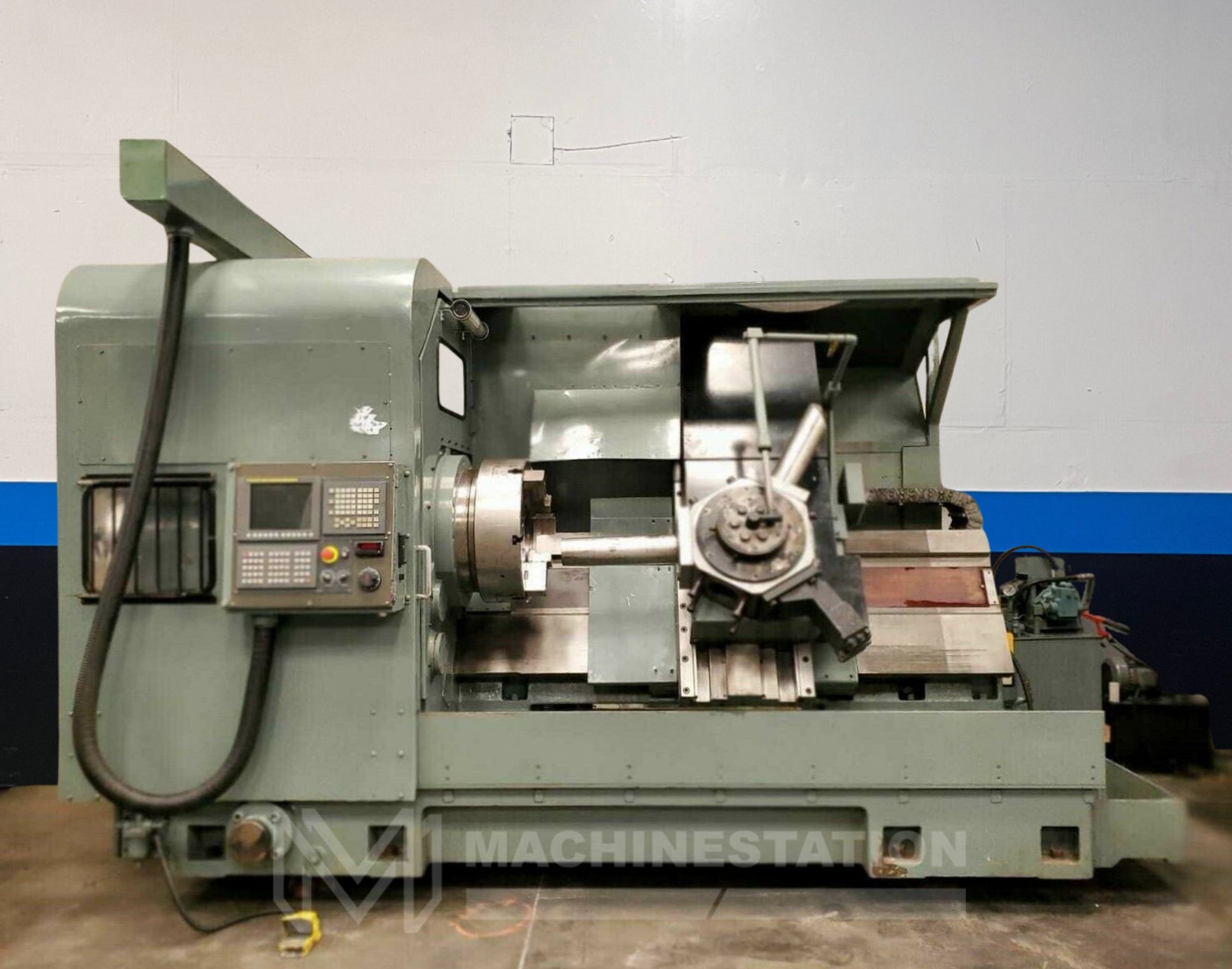

What are the Types of CNC Machines Used for Medical Machining?

Here are the different types of CNC machines that are used for manufacturing different medical products and instruments:

- Swiss type lathes: These are a special type of lathes that are designed for manufacturing small sized, high precision parts. These machines are referred to as the workhorses for micromachining work. The long and slender parts are also made using these types of CNC machines. These machines are perfect for bone screws, catheter hardware, mini valves, and surgical instruments for minimally invasive surgery.

- Multi axis CNC machining centers: All 3-axis, 4-axis, and 5-axis machining centers are used for the manufacturing of different medical parts. The 3 or 4 axis is used for less complex products like enclosures for medical equipment and simple surgical handles, while 5-axis CNC machines are used for manufacturing the most critical designed parts, as they can approach the workpiece from different sides. The 5-axis machining centers are used for making products like dental prosthetics, orthopedic implants, and intricate surgical tools.

- Wire EDM: Wire EDM or Electronic Discharge Machines are also widely used in manufacturing different types of medical products. This machine uses an electrically charged wire for burning away materials from the main workpiece. These machines are unrivaled when it comes to manufacturing products with intricate shapes and designs using materials that are hard to machine. They make cavities for surgical tools, sharp internal corners, bone plates, and molds for plastic components.

Medical Products Manufactured Using CNC Machines:

Here are some of the major medical products that are made using different CNC machines:

- Implants and prosthetics: Different kinds of medical instruments and prosthetics are made using the CNC machines

- Orthopedic and dental implants: This is one of the most important areas of medical manufacturing. Femoral heads, hip stems, bone plates, knee components, spinal cages, dental crowns and bridges, and cranial plates can all be made using CNC machines.

- Cardiovascular implants and prosthetic limbs: Different types of cardiovascular implants, like components for pacemakers, defibrillators, and heart valve replacements, are made using CNC machines. CNC machines are also used for machining lightweight, highly customized, and durable prosthetic limbs that improve mobility and quality of life.

- Surgical instruments: These are another group of medical products that are produced using CNC machines. These tools need sharpness, durability, and precision; all of these can be achieved by using a CNC machine for machining these products.

Different products like scalpels, blades, forceps, clamps, and retractors are made using CNC machines. Drill guides and bone saws are also made using CNC machines, ensuring accurate and controlled cutting during an orthopedic procedure. The minimally abrasive surgical tools are also made using different CNC machines. - Diagnostic and laboratory equipment: Other than implants and tools, different types of medical diagnostic equipment and laboratory testing products are made using different CNC machines.

MRI and CT scanners are made with CNC machined structural frames, housings, and precision parts within these complex imaging systems; they ensure the stability of the machines. Laboratory analyzers are often machined with specific precision using CNC machines. Enclosures for different medical equipment, like patient monitors and ventilators, are made using CNC machines.

Future Trends in Medical CNC Machining:

Here are some of the future trends that can help you become a big medical machining shop in the near future:

- Industry 4.0 and Smart Manufacturing: One of the most striking trends that is shaping the future of manufacturing in every industry, especially the medical manufacturing industry. IoT integration helps with real-time monitoring, predictive maintenance, and workflow optimization. Integration with cloud and data analytics systems helps in smart manufacturing.

- Material innovation: Material innovation is happening at a high speed in the medical manufacturing industry. More biocompatible materials are being used for making medical products using CNC machines. High-performance polymers and bioresorbable composites are finding a new place in the manufacturing arena.

- Micromachining and customization: The demand for smaller products that can actually reach different parts of the human body is increasing at a high speed. Several products, like implantable sensors, are being made using these CNC machines. Other than that, rapid prototyping is also driving the medical manufacturing industry with more customization on a patient basis.

Best Practices for Medical CNC Machining:

Here are some of the best practices that one should implement or follow for medical CNCmachining:

- Design for Manufacturability: Design is very important for proper manufacturing. Avoid designs that bring unnecessary complexity or need different high end tools for machining. Use standard features, and simplify the geometries as much as possible. Also, make sure to follow the recommended wall thickness for both metals and plastics, as thin walls can vibrate during machining.

- Quality control: Medical CNC machining is a very sensitive market, so one cannot compromise on the quality of machining for this industry. Make sure you are using high precision inspection tools for further rechecking the finishing of the products.

- Tooling and toolpath optimization: Selecting the right tool is definitely going to decide the quality of the product that you’re manufacturing. Using high quality carbide or diamon coated tools. Minimize the setups and optimize the toolpaths for a better and smoother machining experience.

Top Medical Products and the Machine that might be Used for Machining it:

Here are some top medical products that are made using CNC machines, and here are the machines you might use to machine that product:

- Hip joint femoral head: Makino D200Z

- Hip acetabular cup: Hermle C 22

- Knee femoral component: DMG MORI NTX 1000

- Tibial tray for knee replacement: Matsuura MX-330

- Spinal pedicle screw: Star SR-20R/IV

- Bone plate (locking plate): Okuma MU-4000V

- Intramedullary nail (IM nail): Mazak INTEGREX i-200H ST

- External fixation clamp: DMG MORI NTX 1000

- Dental implant abutment: Willemin-Macodel 408MT

- Dental implant screw: Citizen Cincom L12

- Orthodontic brackets: Willemin-Macodel 408B

- Zirconia dental crown (milled in green state): Roland DG DWX-53DC

- Custom dental bridge framework: vhf R5

- Surgical bone drill bit: Rollomatic GrindSmart 630XW3

- Orthopedic reamer: Rollomatic GrindSmart 630XW3

- Forceps (surgical grade stainless steel): GF Machining Solutions CUT P 350

- Hemostats: Mitsubishi Electric MV1200R

- Surgical scissors: GF Machining Solutions FORM P 350

- Pacemaker housing (titanium casing): KERN Micro HD

- Surgical needle (machined + ground): Royal Master Grinders – Medical Needle Grinding System

- Catheter introducer components: Tsugami S206

- Neurostimulation implant casing: Okuma MULTUS U3000

- Stent crimping tool (machined fixture/tooling used in production): Haas UMC-500

- Prosthetic limb joint connector: Matsuura MX-330

- Laparoscopic instrument handle: DMG MORI NTX 1000

Conclusion

Medical CNC machining is a tough but interesting field, where you will be able to make products that can help save human lives. So make sure you do the best in this field, and for that you would best machines. To get the best used CNC machines for your machining works, always feel free to contact MachineStation.

New Arrivals