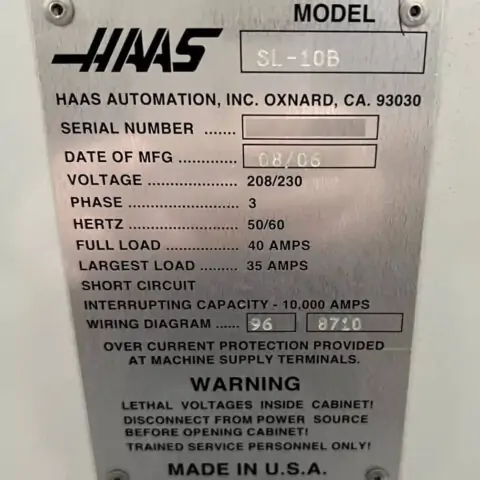

Haas was founded in 1983 by Gene Haas with the motive of making the most reliable machine tools for manufacturing. The company since then has only seen an upper curve of growth, they have been able to convince and then deliver the best results to several manufacturing companies out there especially in the Western world. With that amount of love among the users, Haas became the largest machine tool manufacturer in the Western world. The machines of Haas are meant to deal with several types of engineering works like milling, drilling, boring, and tapping. When Haas entered the business, most people were skeptical about the fact that machines made in the United States of America could even be sold at a price lower than 50,000 USD but the company focused on making economical machines and helping their potential buyers out.

Specialty of Haas machines

Firstly, among all the advantages of owning a Haas machine one of the most striking advantages is the huge machine lineup that Haas brings for you. Even when you are trying to buy used ones from platforms like MachineStation, you get several options because their machines are popular among all the different manufacturers. The company mainly manufactures four different machine lines – vertical machining centers (VMCs), horizontal machining centers (HMCs), CNC lathes, and rotary tables, as well as a number of large five-axis and specialty machines.

Now, coming to the quality of machines of Haas, they have taken proper care of that too. To ensure that the machines are of the best quality in the market, they have decided to build most of the critical parts of the machine in house. They also have a highly trained group of people in their plants for the mechanical and electrical assembly jobs, helping the company to maintain quality, cost, and accuracy.

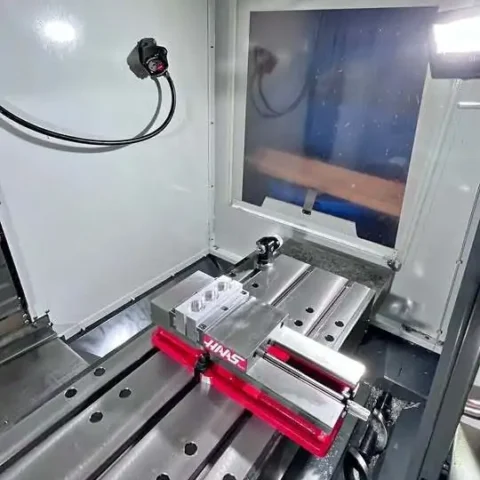

Also, their machines come second to none when the discussion is about top notch features, integration of modern technology, and automation features. They have never failed to win the race of bringing the best feature by introducing attractive features like sturdy workstations, accessible coolant and air hoses, and high-impact safety glass doors. Their machines are also pretty versatile helping their customers to do different works like heavy and critical engineering work and also fine detail work.

Why Choose used Haas CNC machines?

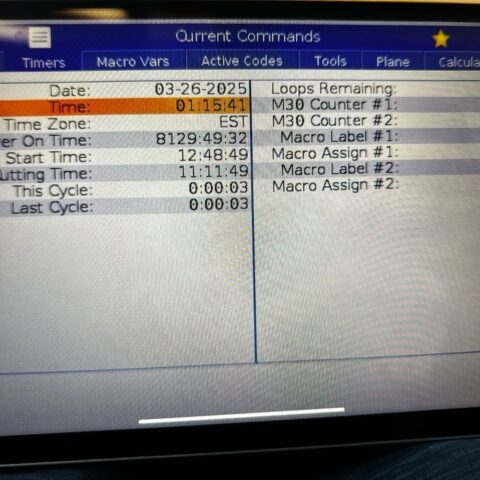

- User friendly Haas control systems – One of the best features of the Haas CNC machines is the user friendly control systems of the CNC machines. Operators will easily be able to learn how to operate the machines and they will be able to adapt to the new machines. If it is a big plant then the operators can work with different CNC machines at a time because it is easy to learn and operate them. Different features like VPS and WIPS further enhance usability.

- Reliable and high performing spindles – Spindles are one of the most important parts of the CNC machines. The machines with the right spindles can improve the accuracy of your machining works by several times. Also, Haas makes all their spindles in house which gives you a quality assurance and they are also available at different speeds. Their spindles also have a high torque option making the machines a good choice for your business.

- Automation integration facilities – Automation is the new normal for manufacturing business. Several factories have even become automated with no human labor. You get a lot of automation integration facilities with the Haas CNC machines. Automated tool managers, pallet changers, and robotic feature integration options are available for you with the Haas CNC machines. Several advanced features like look-ahead algorithms and high-speed machining support are also available with these machines, making it a convenient option for machining works.

- Robust construction – Strong CNC machines are very important for complex engineering works, because with high vibration the accuracy of the product may get damaged. The rigid cast iron construction of the Haas CNC machines ensures that the machine is stable during high power works. The rigid construction of the machine also extends machine life and maintains precision over years of intensive use, that’s why buying used versions is also a great deal for you.

Global support network – One thing about CNC machines is that you may need customer servicing, help with installations or even new parts for your machines on frequent basis and in that case Haas CNC machines becomes a great choice for you as you can get access to their global support network for any kind of help that you need.

Top Haas CNC machine that you should look for

- Haas TM-1 Tool Room CNC Mill

- Haas ST-10 CNC Turning Center – Lathe

- Haas VF-2SS CNC Vertical Machining Center With Robot Package – 2022

- Haas VF-2SS CNC Vertical Machining Center – Mill

- Haas TL-2 CNC Tool Room Lathe with Tailstock – 2022

- Haas EC-2000 CNC Horizontal Machining Center – 4th Axis Mill

When it comes to buying CNC machines, Haas should be one of your top priorities because of the different top notch features they provide like the high speed and high torque spindles, and also the different automation features. They also have a huge range of machines, with support networks around several countries in the world. If you want any specific type of machine with a particular feature then let us know your requirements in the Machinery Locator form and we will help you out.

Showing 1–20 of 232 resultsSorted by latest