*All specifications are approximations and are subject to verification. Comes as shown in the images. Please give us a call if you have any questions before purchasing. All sales are final.*

| Make: | Okuma |

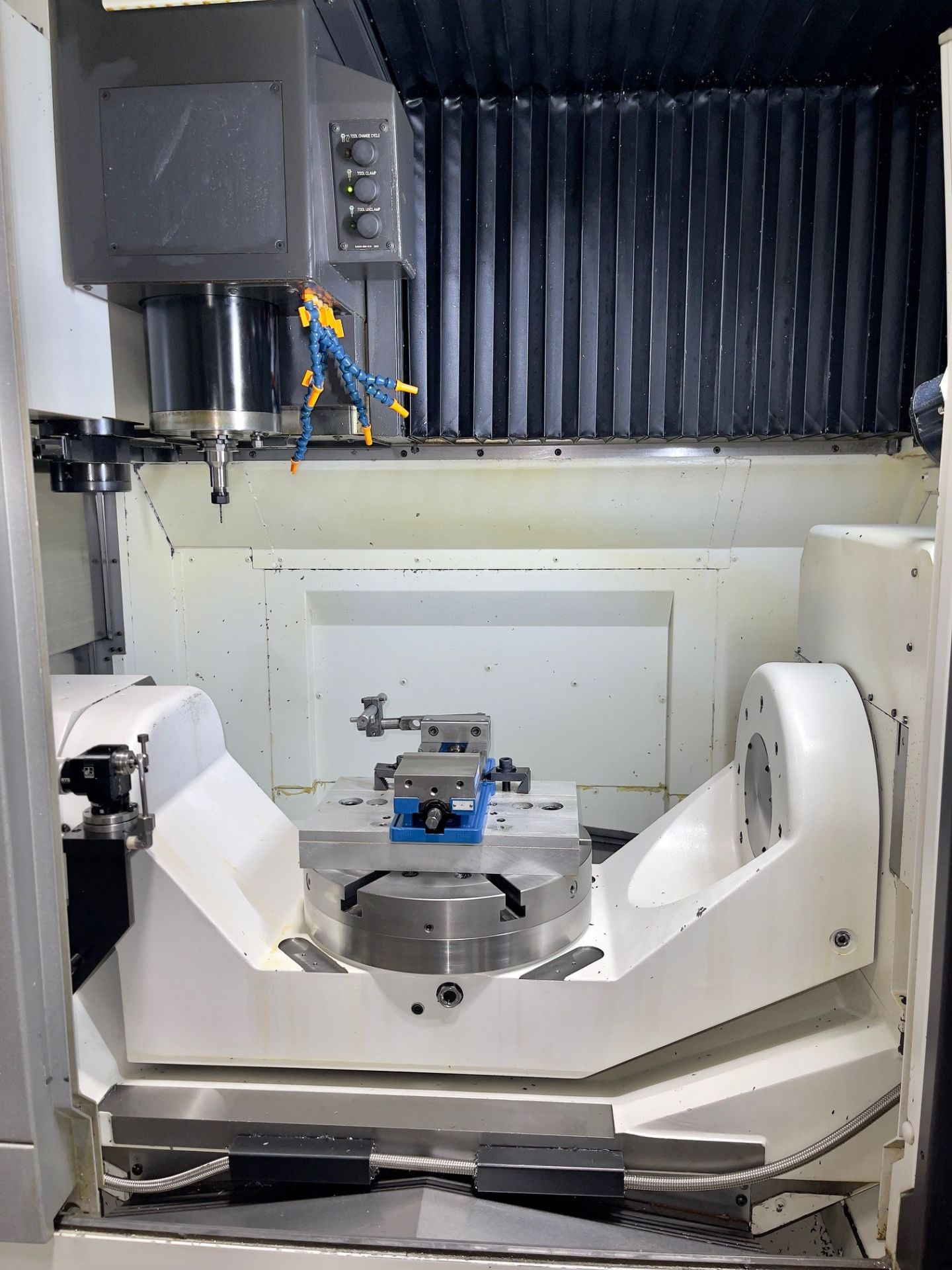

| Model: | Genos M460V-AX |

| Year: | 2018 |

| Condition: | Used – Good |

| Machine Type: | 5-Axis CNC Vertical Machining Center |

| Country of Origin: | Japan |

| Equipped With: |

|---|

- Full 5-Axis Simultaneous Machining

- Okuma OSP CNC Control (OSP-P300 / OSP-P2000 Series)

- High-Speed Spindle

- Automatic Tool Changer

- Rigid Tapping

- Integral Roller Guideways on X / Y / Z

- Linear Scales (Factory Option)

- CNC Rotary Table (A & C Axes)

- Flood Coolant System

- Chip Conveyor Ready

- Spindle Cooling

- Fully Enclosed Guarding

- Work Light

- Manual Pulse Generator (MPG) Pendant

|

| Axis Travels: |

|---|

- X-Axis Travel: Approx. 45.3″ (1,150 mm)

- Y-Axis Travel: Approx. 31.5″ (800 mm)

- Z-Axis Travel: Approx. 31.5″ (800 mm)

- A-Axis (Tilt): ±120°

- C-Axis (Rotation): 360° Continuous

- Simultaneous 5-Axis Machining Capability

|

| Table / Trunnion: |

|---|

- Table Diameter: Approx. 600 mm (23.6″)

- Maximum Table Load: Approx. 500 kg (1,100 lbs)

- High-Accuracy 5-Axis Rotary Table

- C-Axis Continuous Rotation with A-Axis Tilt

|

| Spindle: |

|---|

- Spindle Taper: CAT 40

- Maximum Spindle Speed: 12,000 RPM

- Spindle Motor Power: Approx. 20 – 25 HP (15 – 18.5 kW)

- High-Speed, Rigid Spindle for Contouring & Light Milling

- Oil-Air Spindle Lubrication / Cooling

|

| Automatic Tool Changer: |

|---|

- Tool Capacity: 30 – 40 Tools (Configuration Dependent)

- Random Access Tool Selection

- Maximum Tool Length: Approx. 300 mm (11.8″)

- Maximum Tool Weight: Approx. 8 – 10 kg (17 – 22 lbs)

|

| Feedrates: |

|---|

- Rapid Traverse (X / Y / Z): Approx. 1,500 – 2,000 mm/min (Typical)

- Cutting Feedrate Controlled by Okuma CNC Look-Ahead

- High-Precision AC Servo Drives

|

| CNC Control: |

|---|

- Okuma OSP CNC Control (OSP-P300 / OSP-P2000 Series)

- Large Color LCD Display

- Conversational & G-Code Programming

- 5-Axis Tool Center Point Control (TCP)

- High-Speed Look-Ahead & Interpolation

- Ethernet / USB Connectivity

- Collision Avoidance & Thermal Compensation (Optional)

|

| Coolant & Chip Management: |

|---|

- Flood Coolant System

- Programmable Coolant Nozzles

- Optional High-Pressure Coolant Ready

- Chip Conveyor Interface (Machine Dependent)

|

| Electrical: |

|---|

- Voltage: 230 / 400 / 480 V (Field Configurable)

- Phase: 3-Phase AC

- Frequency: 50 / 60 Hz

- Control Voltage: AC 100 V / DC 24 V

- Industrial Electrical Cabinet with Safety Interlocks

|

| Machine Construction & Accuracy: |

|---|

- Rigid Cast Construction with Integral Guideways

- High-Torque Spindle Design

- Excellent Thermal Stability

- High-Accuracy Spindle Bearings

- Optional Linear Scale Feedback on All Axes

|

| Typical Applications: |

|---|

- Precision 5-Axis Contouring

- Aerospace Structural Parts

- Automotive Prototypes

- Mold & Die Components

- Medical Components

- Sculptured Surface Machining

|

| Quick Highlights: |

|---|

- True 5-Axis Simultaneous Machining

- Proven Okuma OSP Control Platform

- Rigid, High-Accuracy Vertical Machining Design

- Excellent Balance of Power, Speed & Precision

|