Oil and Gas

Table of Contents

- All About Oil and Gas CNC Machining

- What is Oil and Gas CNC Machining?

- How Does CNC Machining Help the Oil and Gas Industry?

- Materials Used in the Machining of Oil and Gas Industry Products

- Top Oil and Gas Industry Products that are Manufactured using CNC Machining

- Top Practices for Manufacturing Oil and Gas Industry Parts Using CNC Machine

- Future Trends in the World of Oil and Gas Products CNC Machining

- Top Oil and Gas Industry Parts and their required CNC Models

- Conclusion

Quick Contact

All About Oil and Gas CNC Machining

According to a report, the global medical device contract manufacturing market size is estimated to be $ 76.8 billion in 2024, and the market is expected to reach $ 151.98 billion approximately by 2030, growing at a CAGR of 12.36%.

Oil and gas are one of the largest and most profitable business sectors in the whole world. The industry is kind of the lifeline of the global economy, and the lifeline to this industry are the pipelines and refineries. These refineries and pipelines feature several components that are made with the use of CNC machines. From drilling components, pipeline components, to offshore and subsea equipment, everything is made with the help of CNC machines.

The products used in this industry are generally very costly because they’re made up of high quality materials and made for durability, because these parts are not changed on a frequent basis. A small leakage or problem with the products can also lead to fatal accidents, so it is very important to make sure that the parts are made with high precision, which ensures good performance for the long term.

If you’re someone who is planning to get into this industry and start machining products for this industry, then you have definitely made a great choice. Now, you need to know a lot of things, which machines to use, which materials to use, and what products are made using what machines. To know all that, let’s take a deep dive!

What is Oil and Gas CNC Machining?

Oil and Gas CNC machining is the industry of manufacturing different products that are utilized by this energy sector for different purposes, and they’re all mostly made with the help of different styles of CNC machines. High end CNC machines with well trained operators are also a huge need in this machining sector. Hard metals with corrosion resistance features are mostly used for manufacturing different products in this industry. The products need to withstand extreme conditions, which include:

- Temperature ranges from -196°C to +800°F

- Pressures exceeding 15,000 psi

- Corrosive environments with seawater, H2S, and CO2 exposure

- 24/7 operational demands with minimal downtime tolerance

How Does CNC Machining Help the Oil and Gas Industry?

Here are some of the main ways in which CNC machining helps in the manufacturing of different products for the Oil and Gas industry:

- Unparalleled precision: One of the biggest advantages that the CNC machines bring to the table when it comes to manufacturing is unparalleled precision and tight tolerances. They need tolerances measured in micrometers. CNC machines can repeatedly achieve these tolerances, which is important for implants and instruments.

- Complex geometric capabilities: The modern advanced 5-axis CNC machines can create complex design products. Multi axis CNC machines, like 5-axis or 7-axis, can produce these complex design parts in just one setup while reducing time and error.

- Regulatory compliance support: oil and gas industry products need to follow a lot of regulatory compliance, or they become useless, and that level of perfection in manufacturing is hard to achieve with traditional machining methods. CNC machines become vital in these scenarios.

- Rapid prototyping: R&D is very important in this industry, and there is also a high demand for custom products for different geographical circumstances, which can be easily done with the help of CNC machines. The CNC machines can easily make the most complex of designs with ease, while traditional machining methods might not be able to do it.

- Safety: Most of the products of the oil and gas industry are made up of heavy and demanding materials that are not easy to machine, and if done manually, then it can cause major accidents. CNC automated machining minimises human intervention, helping to provide safety to machinists during manufacturing.

Materials Used in the Machining of Oil and Gas Industry Products:

Here are the major materials that are used for machining different products for the oil and gas industry:

- Stainless steel alloys: One of the most commonly used materials in the oil and gas industry is stainless steel alloys. 316/316L stainless steel dominates corrosion-critical applications. With this material, you can get outstanding corrosion resistance in marine environments. They have high ductility for complex forming operations and excellent weldability for field assembly. But as this is a hard material so it will need specific tools and specific cutting strategies to machine this material.

- Titanium: This is another widely used material in the oil and gas industry. They have a high strength to width ratio. This material is also well known for being able to resist corrosion in deep sea environments. Titanium also has excellent weldability and excellent fatigue properties. But as an expensive material, you need to be very careful about precision during machining titanium products.

- Nickel alloys: One of the most common nickel alloys that is used in manufacturing products of the oil and gas industry is the Inconel series. They have exceptionally high temperature strength for downhole applications. These materials also have a high level of corrosion resistance in acidic environments. They can be used to make wellhead components, sour gas parts, and valves.

- Carbon steel: Last but not least, carbon steel is also very commonly used for manufacturing different products for the Oil and gas industry. They are the cost effective solution for standard pressure applications, and have an excellent strength to weight ratio for structural applications. They are used for making casings and other structural components.

Top Oil and Gas Industry Products that are Manufactured using CNC Machining:

Here are some of the major oil and gas industry products that are made with the help of CNC machines:

- Drilling equipment components: One of the most necessary products for the oil and gas industry is the drilling products that do the main job for them. Different drill bits and cutting tools are made with the help of CNC machines. Tri cone drill bits, drill collars, and stabilizers are all made with the help of CNC machines. Downhole tools like rotatory steerable systems and downhole motors are also made with the help of CNC machines.

- Wellhead and production equipment: Different wellhead and production products of the oil and gas industry are made with the help of CNC machines. Casing heads with precise threading and tubing heads needing high dimensional control are all made with the help of CNC machines. Both ram preventers and annular preventers are made using CNC machines.

- Pump and compression system: Different pump and compression systems are made using CNC machines, as they demand a superior quality of surface finish for smooth fluid transfer during extraction and refining. Centrifugal pump components like impellers, pump casings, shaft components, and wear rings are made using different types of CNC machines. Plunger pumps and gear pumps are also made using CNC machines, while different compressor elements like impellers, valve components, and cylinder components are made with CNC machining too.

- Refinery and processing equipment: Different processing equipment that needs high technical quality and pressure tolerance is made with the help of CNC machining. Tube sheets, shell and tube assemblies, and baffle systems are made with the help of CNC machines. All types of pressure vessels, like separator vessels and reactor vessels, and storage tanks, are made using CNC machines. Distillation trays for precise perforations and packing support systems for mass transfer columns are made with CNC machining, too.

Top Practices for Manufacturing Oil and Gas Industry Parts Using CNC Machine:

Here are some of the major recommendations from our side about best practices to follow while machining oil and gas industry parts using CNC machines:

- Choose the right tool and speed: Selecting the right tool is the first step towards doing the right machining. The selection of the tool depends on the quality of the tool, as demanding materials need hard tools for machining work. Use sharp cutting tools to prevent work hardening. Also, make sure to maintain a constant feed rate to avoid heat buildup, and select positive rake angles for better chip formation.

- Follow precision enhancement techniques: You should do machining with a focus on tight tolerance achievement for better product quality and the growth of your business. Implement temperature compensation for better dimensional stability, and apply stress relieving operations between rough and finish passes. Make sure to apply proper tool path strategies for minimizing tool marks.

- Production efficiency optimization: Try to make the whole machining process much more efficient for your business’s benefit. Implement standardized fixturing for part families, use modular tooling systems for quick changeovers, and develop standard operating procedures for consistent results. Focus on tool life optimization, too. Implement a tool condition monitoring system and maintain optimal cutting conditions throughout the cutting process for better tool life.

Future Trends in the World of Oil and Gas Products CNC Machining:

Here are some of the trends that are shaping the future of manufacturing products in the oil and gas industry:

- AI driven manufacturing: Like any other industry, AI is disrupting the manufacturing industry too. Predictive maintenance applications have been hugely helpful in decreasing the downtimes, with real time monitoring systems and quality production models. Adaptive machining parameters and automated toolpath optimization help in better optimization of the machining process.

- Advanced materials and coatings: Next generations alloys are being used in the machining of products for the oil and gas industry. Hybrid materials combining different alloy properties are also being used for manufacturing in the oil and gas industry. Advanced surface treatment methods are also being used for enhanced corrosion resistance. PVD (Physical Vapor Deposition) coatings are used on cutting tools to extend lifespan, and ceramic coatings are used for high temperature applications.

- Industry 4.0 and digital manufacturing: IoT integration has helped significantly in Industry 4.0 manufacturing methods. Digital twins of the manufacturing process are used for optimization. For fleet-wide optimization, cloud based data analytics is used. Remote monitoring capabilities are helping with offshore manufacturing support and augmented reality for maintenance and troubleshooting.

- Advanced technological usage: Different advanced technologies are also being employed for better manufacturing. Hybrid manufacturing of additive-subtractive combinations is being used for manufacturing products with complex geometries. In-situ quality monitoring is used during manufacturing, and multi material processing in a single setup is also being done.

Top Oil and Gas Industry Parts and their required CNC Models:

Here are some of the major oil and gas parts that can be machined using a CNC machine, and the machine models that you might use:

- Drill Bits: Haas VF-4

- Drill Collars: Mazak QT-350MY

- Drill Pipes: Doosan Puma 5100LY

- Stabilizers: Okuma LB3000 EX II

- Downhole Tools: DMG Mori NLX 3000

- Casing Hangers: Mighty Viper VMC-2100

- Mud Motor Components: Haas ST-30Y

- Wellhead Housings: Mazak Integrex i-400

- Christmas Tree Assemblies: Doosan Mynx 9500

- Blowout Preventer (BOP) Bodies: Okuma MU-6300V

- Casing Heads: DMG Mori DMU 75 monoBLOCK

- Tubing Heads: Haas UMC-750

- Subsurface Safety Valves: Mazak Quick Turn 250MSY

- Frac Valve Bodies: Doosan DNM 6700

- Gate Valves: Okuma GENOS L4000-e

- Ball Valves: Haas ST-20Y

- Choke Valves: Mazak VTC-800/30SR

- Check Valves: DMG Mori CTX beta 1250 TC

- Control Valve Bodies: Mighty Viper VMC-1300

- Flanges: Doosan Puma GT2600

- Pipe Fittings: Haas VF-2SS

- Manifolds: Makino a81nx

- Heat Exchanger Components: Trumpf TruLaser 3030

- Pump Housings: Okuma MB-5000HII

- Compressor Parts: Mazak Integrex e-670H

- Turbine Components: DMG Mori DMU 210 P

- Hydraulic Cylinder Components: Haas ST-35

- Offshore Platform Fasteners: DMG Mori NLX 4000

- Gear Components: Makino T4

- Flowline Connectors: Doosan NHP 6300

Conclusion:

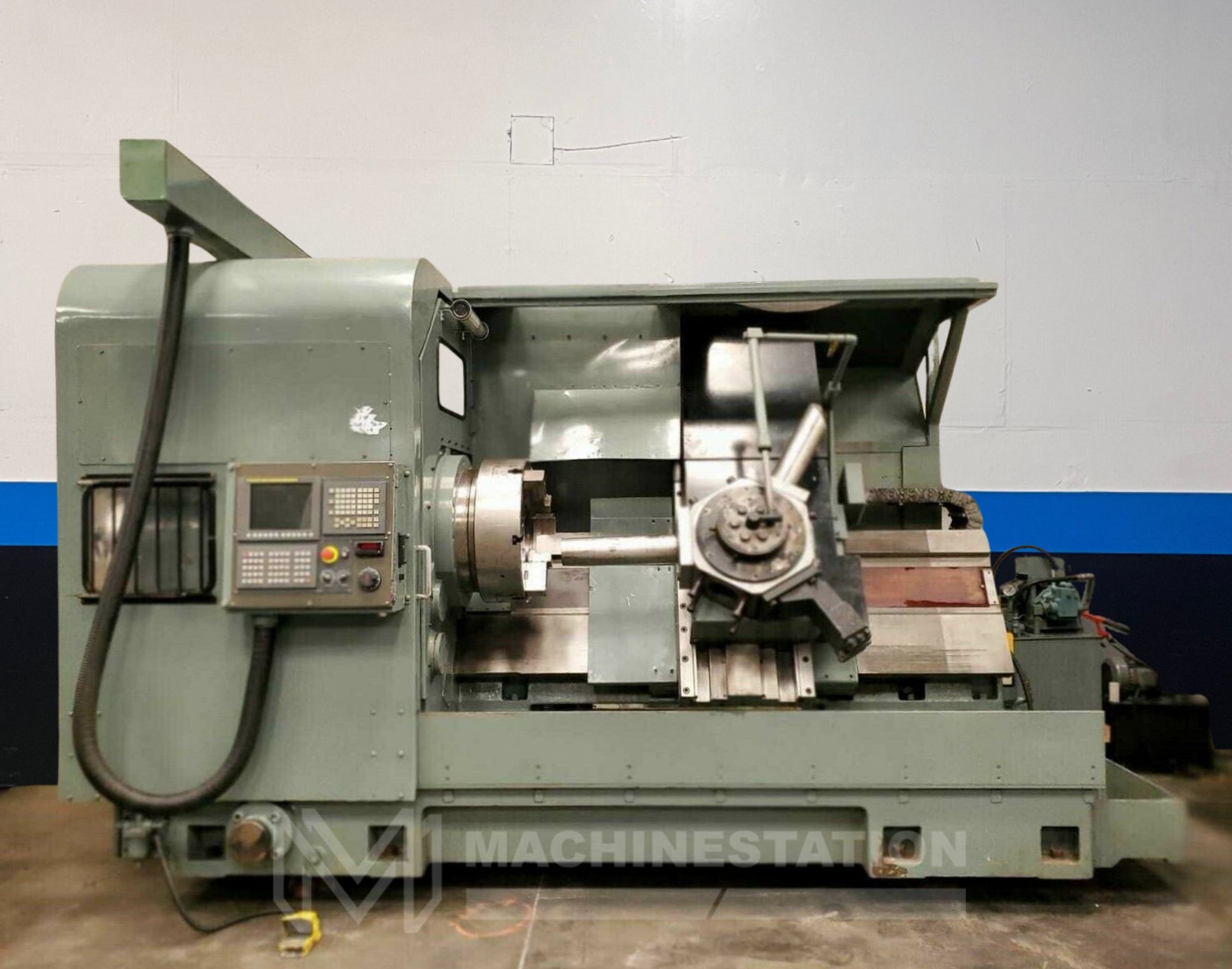

The oil and gas industry is one of the world’s largest industries, which needs a lot of manufacturing work, and the parts are of high price, so anyone entering this industry can make a lot of money. To maximize your profits, you can go with buying used CNC machines from Machinestation to save initial investment and then doing machining works following best practices to get the best results.

New Arrivals