*All specifications are approximations and are subject to verification. Comes as shown in the images. Please call us if you have any questions before making a purchase. All sales are final.*

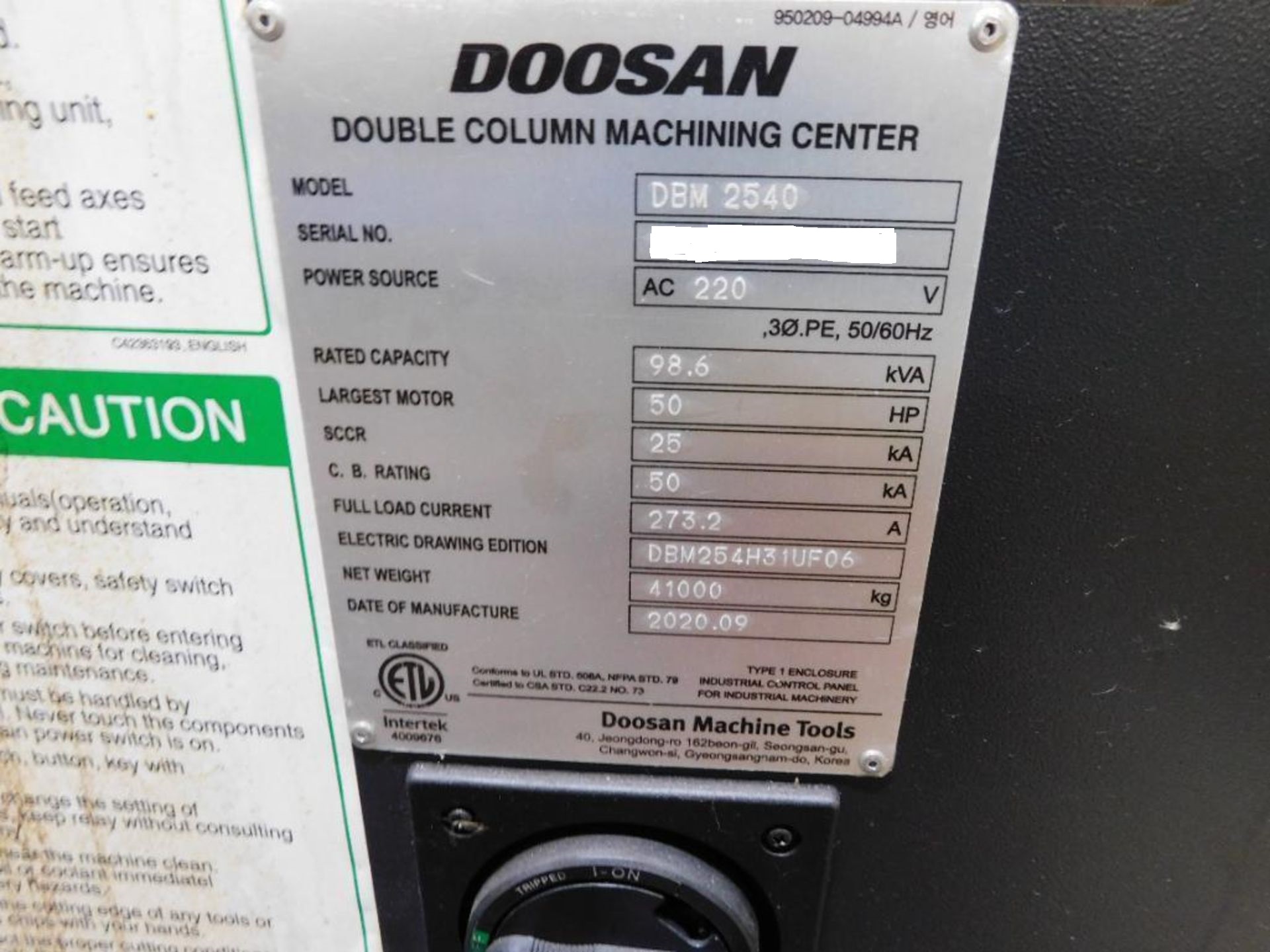

| Make: | Doosan |

| Model: | DBM 2540 |

| Condition: | Used |

| Machine Type: |

|---|

| Multi-Purpose Double Column Machining Center |

| Designed for Heavy-Duty Cutting, Large Parts, Dies & Molds |

| Ram-Type Structure (No W-Axis) |

| Travels & Work Area: |

|---|

| X-Axis Travel: 167.3″ |

| Y-Axis Travel: 118.1″ (145.7″ with ATC & AAC) |

| Z-Axis Travel: 31.5″ (Optional 43.3″) |

| Distance Between Columns: 98.4″ |

| Table to Spindle Nose Distance: 39.4″ (Optional 51.2″) |

| Table: |

|---|

| Table Size: 78.7″ × 157.5″ |

| Max Table Load: 44,092 lbs |

| T-Slots: 24H8 (Optional 28H8) |

| Feedrates: |

|---|

| Rapid Traverse X/Y/Z: 787 / 787 / 591 IPM |

| Max Cutting Feedrate: 394 IPM |

| Spindle: |

|---|

| Ram Spindle Size: 15″ × 15″ |

| Spindle Speed: 6,000 RPM (Optional 8,000 RPM) |

| Spindle Motor Power: 49.6 HP Continuous / 73.8 HP (25% Duty) |

| Max Spindle Torque: 745 ft-lbs |

| Tool Taper: ISO #50 |

| Tool Shank Options: BT50 (Std), CAT50 / DIN50 (Opt) |

| Automatic Tool Changer (ATC): |

|---|

| Tool Capacity: 40 Tools (Optional 60 / 90) |

| Max Tool Diameter: 5.1″ (9.8″ Adjacent Empty) |

| Max Tool Length: 15.7″ |

| Max Tool Weight: 66.1 lbs |

| Tool Change Time (Tool-to-Tool): 5.5 sec |

| Tool Selection: Fixed Address |

| Automatic Attachment Changer (AAC): |

|---|

| 2-Station + 1-Station (Swing or Up-Down Type) |

| Automatic Change of Dummy Cover |

| 90° Angle Head |

| Extension Heads |

| Universal Heads |

| CNC Control: |

|---|

| FANUC 31i CNC Control (Standard) |

| HEIDENHAIN TNC 640 (Optional) |

| SIEMENS 840D (Optional) |

| DSQ I / II / III High-Speed Processing Functions |

| Optional Linear Scale Feedback (X/Y/Z) |

| Structural & Accuracy Features: |

|---|

| High-Rigidity Double-Column Symmetrical Structure |

| M-Type Cast Iron Bed for Vibration Absorption |

| Roller Type LM Guideways |

| Dual Ball Screw Z-Axis |

| Thermal Compensation System |

| Spindle & Ball Screw Cooling System |

| General: |

|---|

| Machine Height: 224.4″ (Optional 200.8″) |

| Floor Space Required: 292.5″ × 433.1″ |

| Machine Weight (Approx.): 92,593 lbs |