*All specifications are approximations and are subject to verification. Comes as shown in the images. Please give us a call if you have any questions before purchasing. All sales are final.*

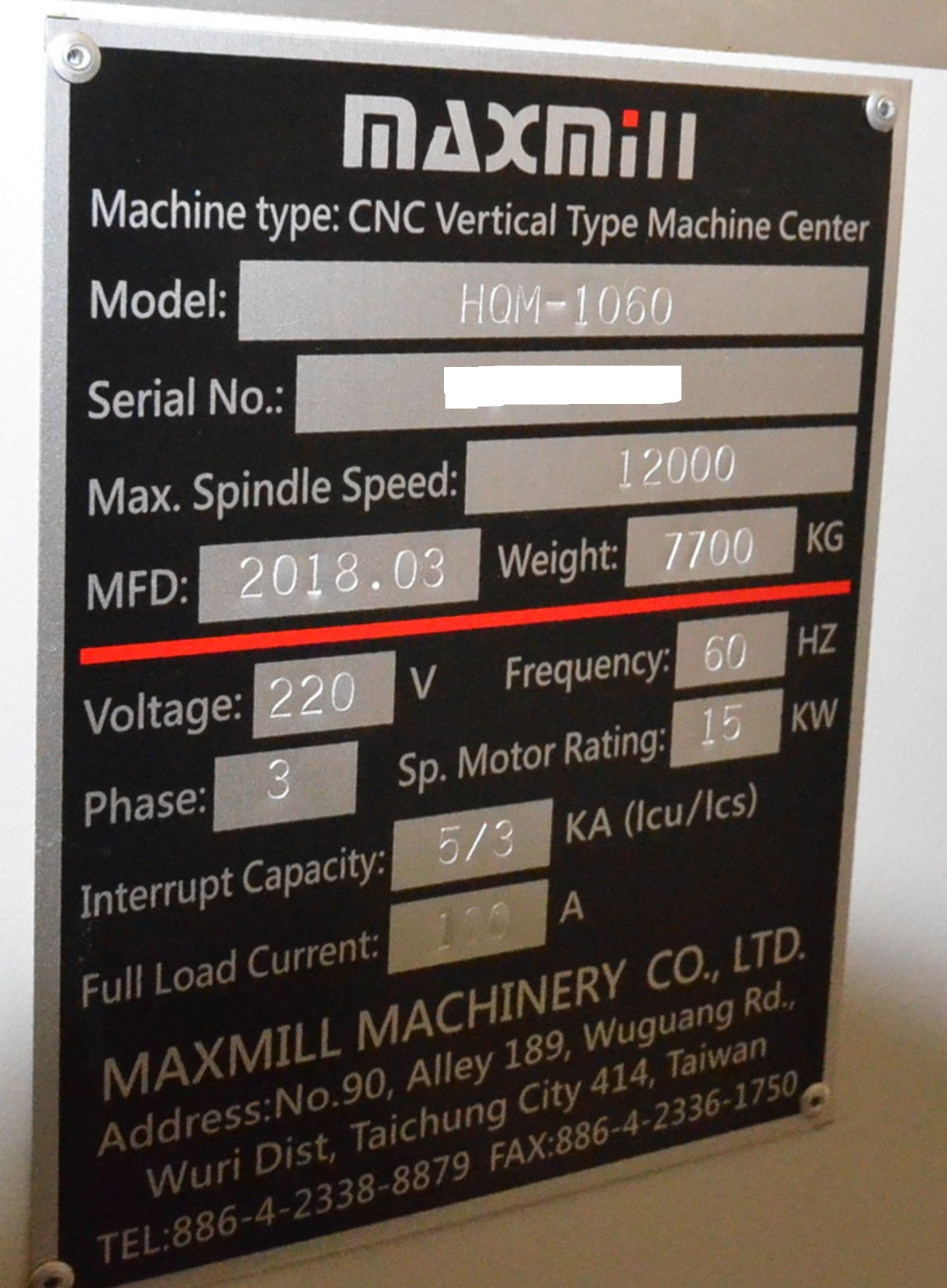

| Make: | MAXMILL |

| Model: | HQM-1060 |

| Year: | 2018 |

| Condition: | Used – Good |

| Machine Type: | CNC Vertical Machining Center |

| Country of Origin: | Taiwan |

| General Information: |

|---|

- Heavy-Duty CNC Vertical Machining Center

- Box / Linear Guideway Construction

- Designed for Medium-to-Heavy Milling Operations

- Rigid Taiwanese Build Quality

|

| CNC Control: |

|---|

- Control Options: Fanuc or Mitsubishi (Machine Dependent)

- ISO / G-Code Programming

- Rigid Tapping

- Helical Interpolation

- Tool Length & Diameter Compensation

- Absolute & Incremental Positioning

- Alarm & Diagnostics Display

- RS-232 / USB Connectivity (Control Dependent)

|

| Axis Travels: |

|---|

- X-Axis Travel: 1,060 mm (41.7″)

- Y-Axis Travel: 600 mm (23.6″)

- Z-Axis Travel: 600 mm (23.6″)

- Linear Guideways on X / Y / Z

- AC Servo Motor Drives

|

| Table: |

|---|

- Table Size: Approx. 1,200 × 600 mm (47″ × 23.6″)

- Maximum Table Load: Approx. 800 kg (1,760 lbs)

- Standard T-Slot Configuration

- Table Height from Floor: Approx. 850 mm

|

| Spindle: |

|---|

- Spindle Taper: BT40 / CAT40

- Maximum Spindle Speed: 12,000 RPM

- Spindle Motor Power: 15 kW (20 HP)

- Belt-Driven, High-Torque Spindle

- Spindle Cooling: Air / Oil-Air Assisted

|

| Automatic Tool Changer (ATC): |

|---|

- ATC Type: Arm-Type

- Tool Capacity: 24 Tools

- Random Tool Selection

- Maximum Tool Diameter: Approx. 80 mm

- Maximum Tool Weight: Approx. 8 kg

|

| Feedrates & Rapids: |

|---|

- Rapid Traverse (X / Y / Z): Approx. 30 m/min

- Maximum Cutting Feedrate: Up to 10,000 mm/min

- High-Precision AC Servo Control

|

| Coolant & Chip Management: |

|---|

- Flood Coolant System

- Coolant Tank with Pump

- Fully Enclosed Splash Guarding

- Chip Tray / Chip Flushing System

- Through-Spindle Coolant (Optional)

|

| Construction & Accuracy: |

|---|

- Meehanite Cast-Iron Base & Column

- High-Rigidity C-Frame Design

- Precision Ground Ballscrews

- Automatic Centralized Lubrication System

- Thermal Stability Design for Accuracy Retention

|

| Electrical Specifications: |

|---|

- Voltage: 220 V

- Phase: 3-Phase

- Frequency: 60 Hz

- Full Load Current: 100 A

- Interrupt Capacity: 5 / 3 kA (Icu / Ics)

|

| Machine Dimensions & Weight: |

|---|

- Approx. Machine Weight: 7,700 kg (16,975 lbs)

- Footprint: Approx. 2,800 × 2,300 mm

|

| Key Features & Advantages: |

|---|

- Powerful 15 kW / 12,000 RPM Spindle

- Large X-Axis Travel for Long Parts

- Rigid, Shop-Friendly VMC Design

- Excellent for Steel & Aluminum Machining

- Strong Price-to-Performance Ratio

|

| Typical Applications: |

|---|

- General Job-Shop Machining

- Mold & Die Work

- Automotive Components

- Fixtures & Tooling

- Medium-to-Heavy Milling Operations

|