*All specifications are approximations and are subject to verification. Comes as shown in the images. Please give us a call if you have any questions before purchasing. All sales are final.*

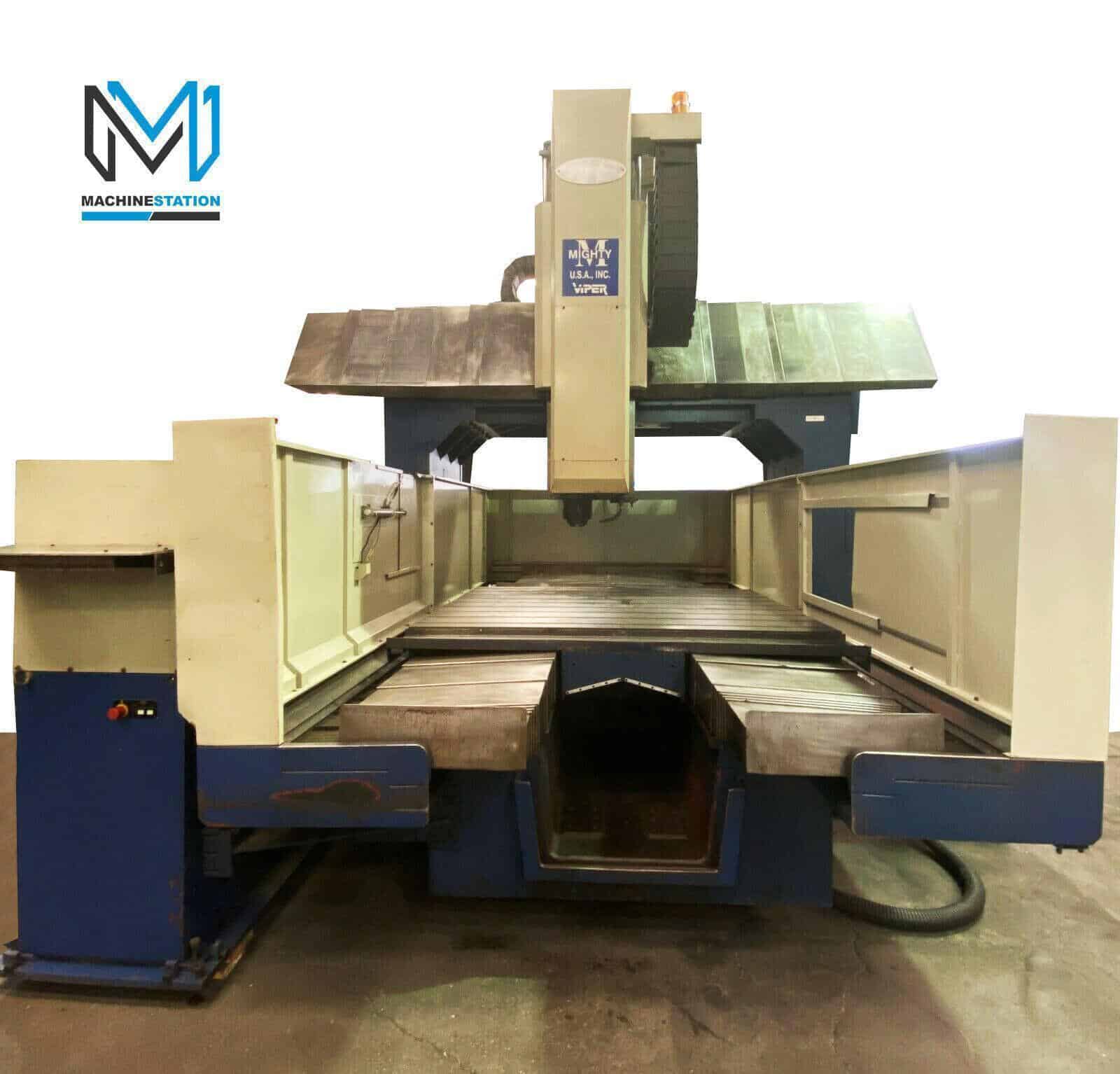

| Make: | Mighty Viper |

| Model: | VTL-16/20M |

| Condition: | Used – Good |

| Machine Type: | CNC Vertical Turning Lathe (VTL) |

| Control: | Fanuc 0i-TD CNC |

| Country of Origin: | Taiwan |

| General Information: |

|---|

- Manufacturer: Mighty U.S.A. Inc.

- Designed for Heavy-Duty Vertical Turning, Boring, Facing & Milling

- M-Series with Live Tooling & C-Axis Capability

|

| Capacity: |

|---|

- Chuck Size: 16″ (Optional 20″)

- Maximum Turning Diameter: Approx. 20″

- Maximum Swing Diameter: Approx. 22″

- Maximum Turning Height: Approx. 16″–18″

- Table Load Capacity: Approx. 2,000–3,000 kg (4,400–6,600 lbs)

|

| Table / Spindle: |

|---|

- Table Type: Vertical Rotary Table

- Table Diameter: 16″ / 20″

- Spindle Orientation: Vertical

- Spindle Speed Range: 0 – 2,000 RPM (Variable)

- Spindle Motor Power: Approx. 20–25 HP

- High-Torque Geared or Belt-Drive Spindle for Heavy Cutting

|

| Axis Travels & Rapids: |

|---|

- X-Axis Travel: Approx. 12″–14″

- Z-Axis Travel: Approx. 16″–20″

- Rapid Traverse (X / Z): Approx. 600–800 IPM

|

| Turret / Tooling: |

|---|

- Turret Type: Hydraulic Indexing Turret

- Number of Stations: 8 or 12 Stations

- Turning Tool Size: 1″ Square

- Boring Bar Capacity: Approx. 2″

- Live Tooling: Yes (M-Series)

- Full Contouring C-Axis

|

| Live Tool (Milling Capability): |

|---|

- Live Tool Motor Power: Approx. 5 HP

- Live Tool Speed: Approx. 3,000 RPM

- Supported Operations: Milling, Drilling, Tapping

- Interpolated Milling with C-Axis

|

| CNC Control – Fanuc 0i-TD: |

|---|

- Color LCD Display

- Manual Guide i (Conversational Programming)

- Absolute Encoders

- High-Speed Machining Functions

- Rigid Tapping

- C-Axis Contouring

- Custom Macro B

- Ethernet / RS-232 Connectivity

|

| Accuracy: |

|---|

- Positioning Accuracy: ±0.0002″ (Typical)

- Repeatability: ±0.0001″

|

| Machine Construction: |

|---|

- Heavy-Duty Cast Iron Base

- Box-Way Construction for Maximum Rigidity

- Hardened & Ground Guideways

- Centralized Automatic Lubrication System

|

| Chip & Coolant System: |

|---|

- Fully Enclosed Splash Guard

- High-Capacity Coolant Tank

- Coolant Pump

- Chip Conveyor (Side or Rear Mounted)

- Wash-Down Coolant Nozzles

|

| Electrical & Safety: |

|---|

- Fully Enclosed Operator Cabin

- Safety Interlocks

- Emergency Stop System

- Work Light

- Status Tower Light

|

| Standard Features: |

|---|

- CNC Controlled C-Axis

- Live Tooling (M Version)

- Hydraulic Chuck

- Hydraulic Turret Clamping

- Automatic Lubrication System

- Fanuc Servo Drives & Motors

- Chip Conveyor

- Coolant System

- Leveling Pads

|

| Optional / Common Options: |

|---|

- Larger 20″ Chuck

- Tool Presetter

- Parts Probing

- High-Pressure Coolant

- Additional Live Tool Holders

- Tailstock (Configuration Dependent)

|