*All specifications are approximations and are subject to verification. Comes as shown in the images. Please give us a call if you have any questions before purchasing. All sales are final.*

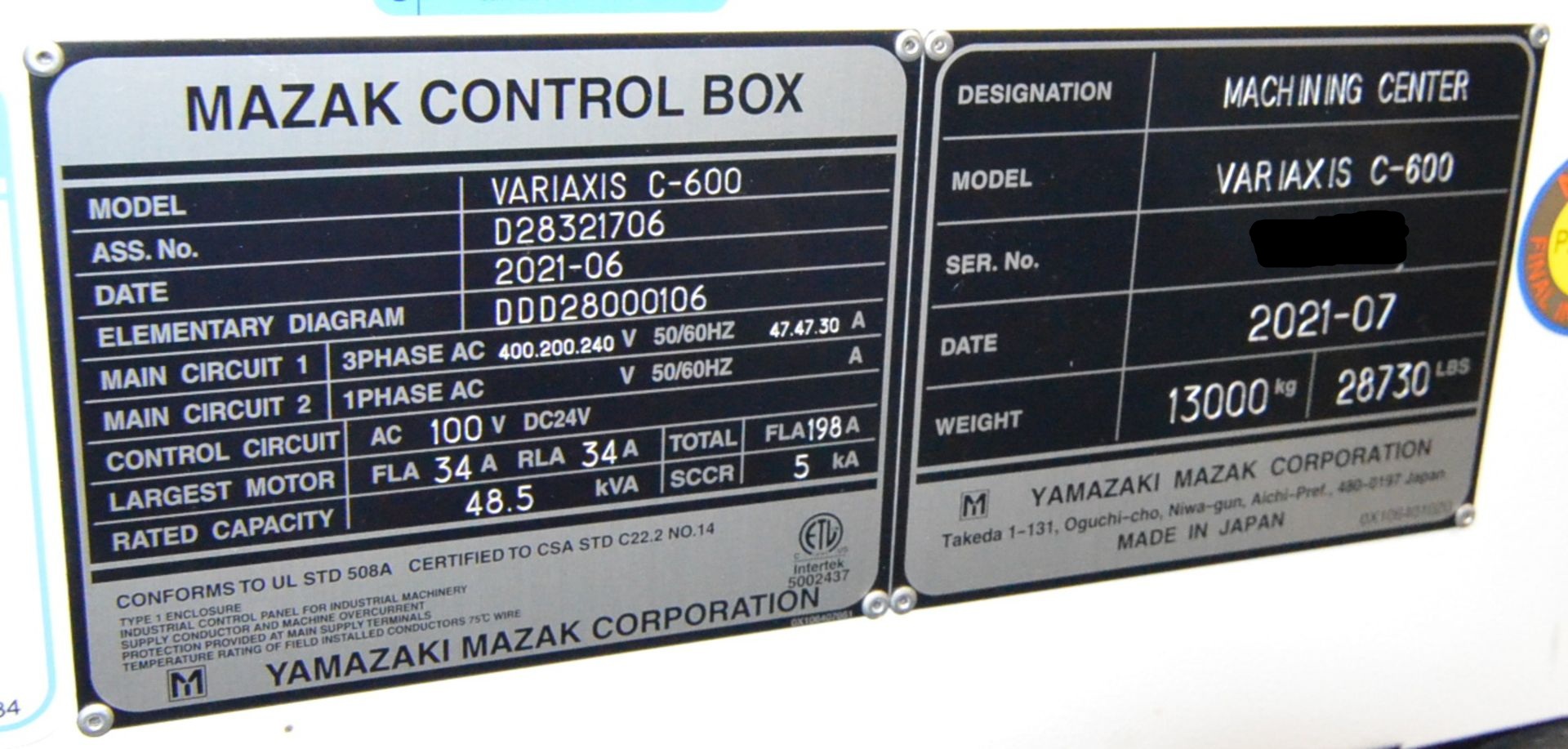

| Make: | Mazak |

| Model: | VARIAXIS C-600 |

| Year: | 2021 |

| Condition: | Used – Good |

| Machine Type: | 5-Axis CNC Vertical Machining Center |

| Country of Origin: | Japan |

| General Information: |

|---|

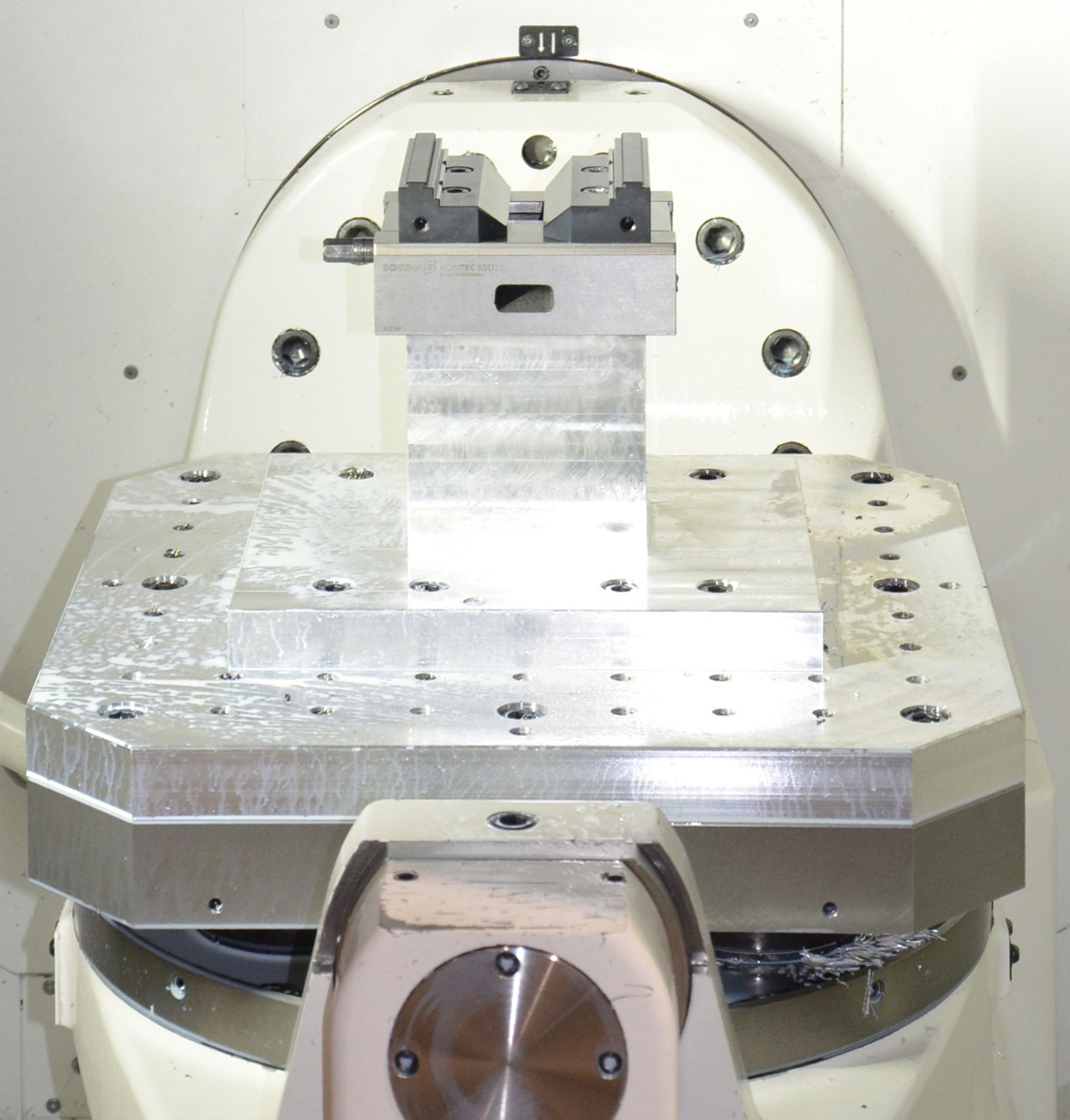

- 5-Axis Vertical Machining Center with Tilting Rotary Table

- Configuration: A-Axis Trunnion & C-Axis Rotary Table

- Designed for High-Precision, Multi-Sided Machining

- Production-Oriented 5-Axis Machining Platform

|

| CNC Control: |

|---|

- Mazak MAZATROL SmoothX CNC Control

- 19″ Color Touchscreen Display

- Simultaneous 5-Axis Control

- Mazatrol Conversational Programming

- EIA / ISO G-Code Programming

- 5-Axis Tool Center Point Control (TCP)

- High-Speed Machining (HSM)

- 3D Interference & Collision Checking

- Program Simulation & Verification

- Ethernet & USB Connectivity

|

| Axis Configuration & Travels: |

|---|

- X-Axis Travel: 650 mm (25.6″)

- Y-Axis Travel: 550 mm (21.7″)

- Z-Axis Travel: 510 mm (20.1″)

- A-Axis (Tilt): −120° to +30°

- C-Axis (Rotation): 360° Continuous

- Simultaneous 5-Axis Machining

|

| Table / Trunnion: |

|---|

- Table Diameter: Ø600 mm (23.6″)

- Maximum Workpiece Diameter: Approx. 730 mm

- Maximum Workpiece Height: Approx. 450 mm

- Maximum Table Load: 500 kg (1,100 lbs)

- Integrated CNC Tilting Rotary Table

|

| Spindle Specifications: |

|---|

- Spindle Taper: CAT 40 (BT40 Optional by Region)

- Maximum Spindle Speed: 18,000 RPM

- Spindle Motor Power: 25 HP (18.5 kW)

- High-Speed Integral Motor Spindle

- Spindle Cooling: Oil-Air / Chilled Cooling System

|

| Automatic Tool Changer (ATC): |

|---|

- Tool Magazine Capacity: 30 Tools (Standard)

- Optional Tool Capacities: 48 / 60 Tools

- Random Tool Selection

- Maximum Tool Length: Approx. 300 mm

- Maximum Tool Weight: Approx. 8 kg

- Tool Life Monitoring & Broken Tool Detection Ready

|

| Feedrates & Rapids: |

|---|

- Rapid Traverse (X / Y / Z): 42 m/min (1,650 IPM)

- Maximum Cutting Feedrate: Up to 32,000 mm/min

- High-Precision AC Servo Drives on All Axes

|

| Coolant & Chip Management: |

|---|

- Flood Coolant System

- Through-Spindle Coolant (TSC) – Optional

- Coolant Filtration System

- Chip Auger / Chip Conveyor – Optional

- Fully Enclosed Splash-Guarded Work Area

|

| Accuracy & Construction: |

|---|

- Rigid Cast-Iron Machine Base

- Roller Linear Guideways on X / Y / Z Axes

- Thermal Displacement Control

- Automatic Central Lubrication System

- High-Rigidity Trunnion Structure for 5-Axis Accuracy

|

| Electrical Specifications: |

|---|

- Power Supply: 3-Phase AC 400 / 200 / 240 V

- Frequency: 50 / 60 Hz

- Control Voltage: AC 100 V / DC 24 V

- Rated Capacity: 48.5 kVA

- Largest Motor Current: 34 A

- SCCR: 5 kA

|

| Machine Dimensions & Weight: |

|---|

- Approx. Machine Weight: 13,000 kg (28,730 lbs)

- Footprint: Approx. 3,300 × 2,800 mm (Option Dependent)

|